Hatch Support Options for Your Boat

April 25, 2023 8 min read

There are few things more undignified and frustrating than holding a hatch open with your head while rummaging through wet beach towels and potato chip bags and snorkel gear for that tube of sunscreen at large in the bottom of the compartment. But convenience is just one of the reasons to install some kind of support device to hold your hatches open. In the case of very heavy hatches — fish box lids with coffin boxes on top, for example — you might actually need assistance lifting the hatch. And, with small kids on board, slamming fiberglass hatches can pose a significant safety concern.

Hatch support devices for storage and access hatches fall into three basic categories — gas shocks, friction hinges and support springs — each of which has its strengths and weaknesses. (Note that there are other options for ventilation hatches and windows that stay open a large part of the time. For extremely heavy hatches, electric lifts are available.)

Contents

Gas Shocks

Gas shocks — also referred to as gas struts and gas springs — look like miniature versions of the shock absorbers on your car. When a certain amount of force is applied, the shock compresses. Gas shocks mount via metal brackets that are connected to the shock with a ball-and-socket joint.

Pros of Gas Shocks:

Gas shocks exert force to help lift hatches as they open, making them feel lighter.

Gas shocks are the only kind of hatch supports that actually assist with opening the hatch. That makes them the obvious choice for large, heavy hatches — and for any hatch that you want to open more easily. They also provide a nice “soft close” feel.

Hatches supported by gas shocks cannot inadvertently slam.

Because gas shocks exert constant force, hatches with correctly sized and installed shocks must be deliberately pushed closed, adding a measure of safety.

Gas shocks are available in many lengths and “forces” for a wide variety of applications.

The force rating of a gas shock refers to the amount of force in pounds required to compress the shock. Common force ratings for marine and RV gas shocks range from 5 lbs. to 120 lbs., meaning gas shocks can be used to lift and support anything from an acrylic electronics box door to a coffin box lid weighing upwards of 100 lbs.

Cons of Gas Shocks:

Measuring for and installing gas shocks isn’t easy.

Designing a gas shock setup from scratch can be bewildering. Shocks can be installed in several different orientations, using a variety of differently shaped brackets. They are also available in numerous lengths and “forces” (the amount of force in pounds required to compress the shock). Measuring for both the extended and compressed lengths, selecting the right brackets and choosing the right force is not for first-time DIYers.

Gas shocks are significantly more expensive than support springs.

A quality, stainless steel gas shock will run in the $40 to $80 range. Stainless brackets are between $5 and $10 each. Painted versions, suitable for freshwater boats, are significantly less. Still, you’re looking at more cost than a $20 support spring.

Gas shocks exert a constant force on fasteners.

Even when fully compressed, gas shock constantly exert the rated amount of force on the fasteners that hold the brackets in place. That can be as much as 120 lbs., requiring solid attachments to solid substrates on both ends. Over time, the constant force from strong gas shocks can even deform some plastics, including Starboard. Take extra care in choosing and installing fasteners and through-bolt when possible. Bedding brackets with an adhesive sealant like 3M 4200 or 5200 adds even more strength.

Marine Friction Hinges

Friction hinges are essentially “sticky” hatch hinges that require a certain amount of torque to move. When you open the hatch, friction hinges hold it stationary in whatever position you leave it. Friction hinges are available in many shapes and sizes to replace existing hinges.

Pros of Friction Hinges:

Friction hinges require no measuring or drilling.

Assuming you’re able to find friction hinges with the same footprint and hole pattern as your existing hinges, installation is just a matter of replacing the old hinges with the new hinges.

Friction hinges don’t impede hatch access.

Both gas shocks and support springs can get in the way of reaching into your hatch from certain angles. Friction hinges add no additional hardware so there’s nothing to get in the way.

Friction hinges hold hatches open in any position.

Unlike gas shocks and support springs — which basically hold hatches in one of two positions, open or closed — friction hinges hold hatches at any angle you choose. This is particularly useful for hatches that you may want to open past 90 degrees, since gas shocks and hinges both limit opening to about 90 degrees.

Friction hinges prevent accidental slamming.

Like gas shocks, friction hinges prevent hatches from falling inadvertently. You have to push the hatch closed, virtually eliminating the chance for bruised heads and smashed fingers.

Cons of Friction Hinges:

Friction hinges don’t provide any opening assistance.

Friction hinges don’t make hatches feel any lighter. In fact, opening a hatch with friction hinges actually requires more effort. If you want a hatch to open more easily, gas shocks are the way to go.

Friction hinges are available in a limited number of force ratings.

Friction hinges require a set amount of torque (rotational force) to move and are not adjustable. Neither are they available in as many different force ratings as gas shocks. Gemlux friction hinges, for example, are either 45 inch-pounds or 20 inch-pounds. If a pair of 45 in-lb. hinges won’t support your hatch, your only option is to add more hinges.

Friction hinges MUST be thru-bolted.

Because of the strain, these hinges put on the fasteners, they can quickly and easily strip out screws. This limits use in some applications where there is not easy access to the “boat side” of the installation for thru-bolting.

Friction hinges aren’t suitable for large or heavy hatches.

Because they’re available in only a few torque ratings, but also because they put a lot of strain on hinge fasteners and hatches, friction hinges aren’t a good solution for heavy duty applications. Unlike gas shocks, which are typically attached to the hatch a third of the way to halfway from the hinge side to the opposite edge, friction hinges support weight right at the hinge edge. To understand the difference, imagine lifting a hatch lid from underneath by pushing with your fingertips either in the middle of the hatch or right next to the hinges. In extreme cases, the added strain created by the lack of leverage can pull screws and even damage fiberglass over time.

Friction hinges are generally the most expensive option.

Quality stainless steel friction hinges run $30 - 50 each — somewhat less than the range for gas shocks. But most applications call for two of them, making them a bit costlier in most applications.

Hatch Support Springs

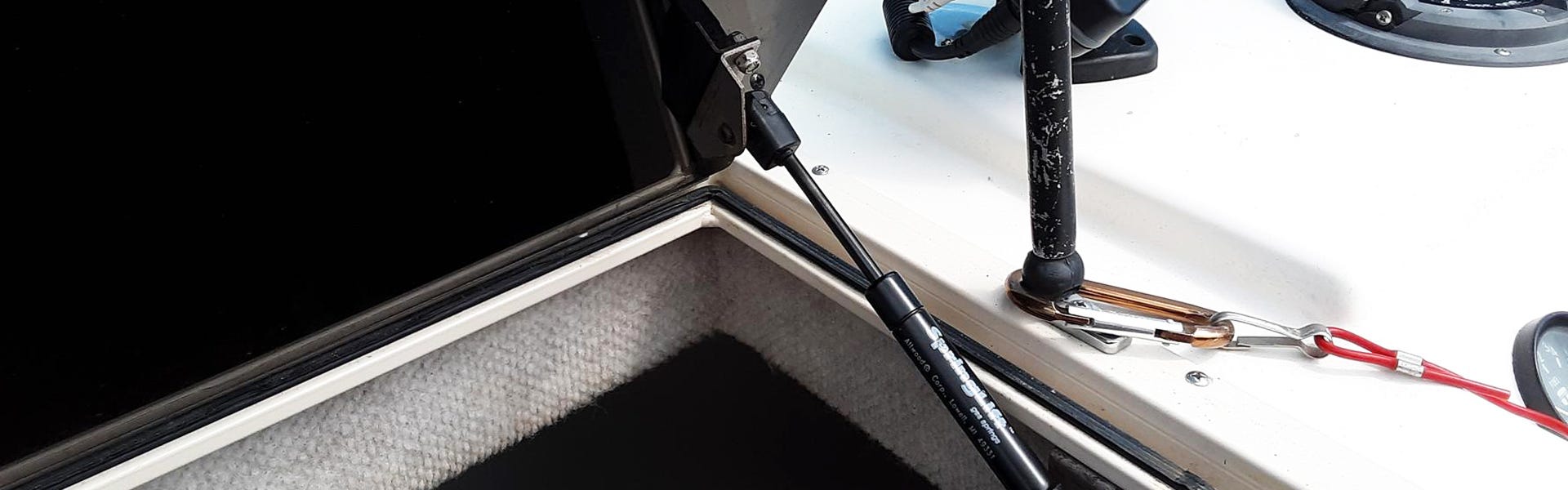

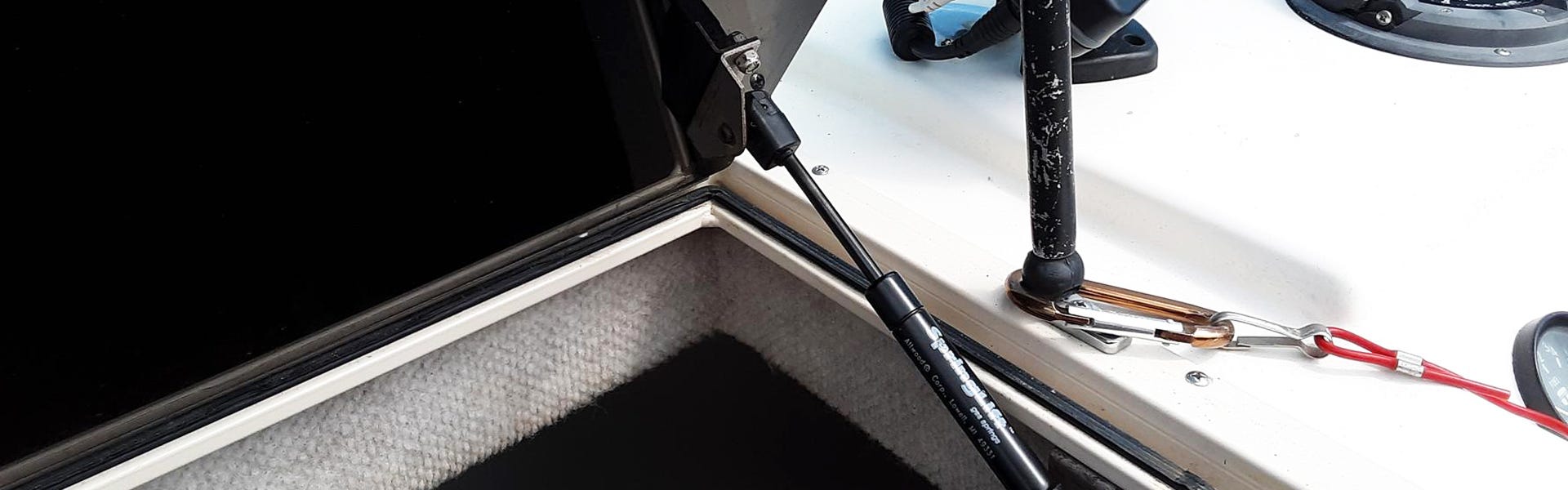

Hatch support springs are an inexpensive alternative to gas shocks. When the spring is straightened, it holds the hatch lid open. Hitting the spring with your hand bends it, allowing the hatch to close. Springs are available in several different lengths and with or without an internal cable that stops the hatch from opening past the point at which the spring is able to straighten.

Hatch Support Spring Pros:

Support springs are easy to measure for and mount.

Installing a support spring on a hatch that doesn’t already have one is much easier than installing a gas shock.

Essentially, you just open the hatch to the position you want, find suitable mounting locations for both ends of the spring, and screw or bolt it in plate. There’s no need to worry about compressed length or how much force is needed. Also, because springs exert little force on their fasteners when the hatch is closed, attachments and substrates don’t need to be as stout as for gas shocks.

Support springs are the least expensive hatch support option.

In the range of $15 to $40, depending on size and material, they are an affordable way to make your hatches more user-friendly.

Hatch Support Spring Cons:

If a support spring is accidentally bumped, the hatch can slam shut.

The biggest drawback to support springs is the fact that as soon as they’re knocked out of their straight position — whether intentionally or accidentally — they provide virtually zero support. That means if you bump the spring while you’re rummaging around in a compartment, the hatch is coming down on your head. If your primary concern is making your boat safer for small children, support springs are not the right choice.

The biggest drawback to support springs is that as soon as they’re knocked out of their position, they provide virtually zero support.

Support springs aren’t suitable for heavy hatches.

Most support springs say they can support up to 20 lbs. But it’s not easy to measure exactly how much weight a spring will have to support in a given application. That requires a calculation involving the weight of the hatch, where the spring is attached to the hatch, and the angle of the hatch when open. The bottom line is that support springs are best for lighter-duty applications — live well lids, electronics box doors, built-in coolers and lightweight fiberglass hatches.