- Home

- Material

Marine Lumber & Sheet Material

Finding the best material for your boat project can be overwhelming - there are many things to consider like application, maintenance, and price point. As an industry leader in marine lumber and sheet material, our team of experts is here to help! » Read More

Learn More About Lumber & Sheet Material

Marine Grade Material

We offer a large selection of marine lumber in a wide variety of thicknesses, colors, and styles. As a manufacturer for the top 200+ boat builders, we’ve been working with these materials for 30+ years and have the expertise to help you decide which material will work best for your project.

Learn more about boat materials here.

What Material Should You Use?

Figuring out what material is going to work best for your project will depend on a few things: Read More

Price: Are you looking to spend top dollar, or get the best bang for your buck? Acrylic and starboard both make great dash panels, but acrylic is considerably more expensive. Deciding your price point is the first step to finding the best marine material.

Appearance: Do you need something with an attractive finish or are you going to be covering the material? Some materials aren’t ideal for visible applications, like starlite or expanded pvc, because their cellular edge can hold dirt and grime over time.

Durability: Are you looking for a material that can hold up to a beating? Some materials are better than others for high impact applications. Acrylic may not be the best option to use in this case as it may crack when put under a lot of force.

Maintenance: Are you someone who doesn’t mind upkeep or would you rather have something maintenance-free? If you don’t want to spend hours oiling up your teak, then a composite material like Starboard may be a better choice.

Ease of Fabrication: Most of our boat materials can be fabricated with common woodworking tools, but some, like acrylic, require special tools to work with. If we’re building your project for you, no worries, but if you’re doing it yourself you need to consider what capabilities you have.

Once you address these points, it’s easy to walk you through the pros and cons each material has for your specific project.

Figuring out what material is going to work best for your project will depend on a few things:

Price: Are you looking to spend top dollar, or get the best bang for your buck? Acrylic and starboard both make great dash panels, but acrylic is considerably more expensive. Deciding your price point is the first step to finding the best marine material.

Appearance: Do you need something with an attractive finish or are you going to be covering the material? Some materials aren’t ideal for visible applications, like starlite or expanded pvc, because their cellular edge can hold dirt and grime over time.

Durability: Are you looking for a material that can hold up to a beating? Some materials are better than others for high impact applications. Acrylic may not be the best option to use in this case as it may crack when put under a lot of force.

Maintenance: Are you someone who doesn’t mind upkeep or would you rather have something maintenance-free? If you don’t want to spend hours oiling up your teak, then a composite material like Starboard may be a better choice.

Ease of Fabrication: Most of our boat materials can be fabricated with common woodworking tools, but some, like acrylic, require special tools to work with. If we’re building your project for you, no worries, but if you’re doing it yourself you need to consider what capabilities you have.

Once you address these points, it’s easy to walk you through the pros and cons each material has for your specific project.

Most Common Marine Materials

Boat Outfitters works with, and supplies many different materials: Read More

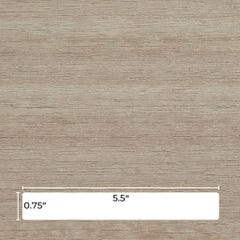

King Starboard: a HDPE sheet designed for the marine environment, it’s a widely popular marine material because it will never rot or delaminate, and is virtually maintenance free. It’s very easy to work with using common woodworking tools, but cannot be glued or bent. Perfect for doors, hatches, storage units, rod holders and tackle boxes.

Acrylic: perfect for dash panels, bent doors, and windshields, acrylic is highly impact resistant and its glossy appearance gives a naturally high-end look. However, it’s the most expensive material and requires special drill bits and extra care when working with it.

Coosa Board: a polyurethane foam filled with strand and woven fiberglass making it as structurally sound as plywood, but weighs about 30-40% less and will never rot or absorb water. Although it will not absorb water or rot, in most cases we recommend covering the material as it is not UV stable and due to the fiberglass composition can be rough on skin. Ideal for decking, bulkheads, and transom replacements.

King Starlite: a lighter weight version of King Starboard that’s less expensive but not as rigid. The reason for it being lighter and less expensive is that when extruded, a blowing agent is added. The tradeoff for this is that it has a cellular edge that dirties easily so it’s not ideal for visible applications. That said, it works well for areas not visible like tackle box shells, upholstery substrates and backing plates.

Teak: popular for its refined, traditional look, but difficult to upkeep and maintain. It’s expensive and overtime will need to be replaced, but if you’re a purist that doesn’t mind taking care of it, Teak is great for decking, doors, hatches and accent pieces.

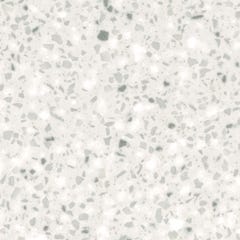

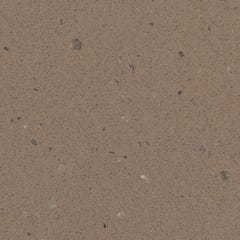

Solid Surface: an easy to work with, less expensive, alternative to other countertop materials. It is available in many attractive colors and designs. That said, it is not as durable as natural stone or granite and has lower heat limitations, but it’s perfect for countertops, vanities and wet bars.

King Starboard AS: Identical to King Starboard, but is extruded with a non skid surface. It has all of the same great weather resistant qualities as King Starboard with the added non-skid texture. Ideal for steps, swim platforms, and floor storage lids.

We’re able to offer full sheet material if you want to get hands-on with your project, or we can custom cut, and assemble your designs if you’d rather sit back and relax. We can get you exactly what you need!

Working on a Custom Project?

While most of our marine materials are relatively easy to work with for a reasonably experienced DIYer, you always have the option of allowing us to handle the engineering and fabrication of your custom boat project. We recieve sketches and templates every day of odd size shapes and patterns customers need custom cut. Pull out that old weathered piece of wood and drop in a direct replacement custom cut to match. Unless working on your boat is a true labor of love, we can help get the job done faster and get you back on the water!

Contact Us

If you’re having trouble finding the exact part you're looking for, the best first step is to take a picture and give us a call.

Our customer service team is here Mon-Fri 8am - 5pm and would love to help you track down the exact hardware you need.

Need Help?

Speak to one of our industry pros:

Tap to Call

Commonly Asked Questions About Marine Material

As an industry leader, and one of the largest consumers of marine grade HDPE, Boat Outfitters is able to provide a wide variety of marine lumber and marine plastic sheet at highly competitive prices. We offer full sheets as well as custom cuts for your projects.

Marine lumber has come a long way from traditional wood. There are now many materials that won’t rot, delaminate and are virtually maintenance-free such as King Starboard, Acrylic and Coosa board to name a few. "Marine Lumber" is now most commonly used as a generic trade name for HDPE plastic sheet -- most commonly off brand King Starboard.

King Starboard: tackle boxes and storage units, console cabin and hatch doors, and fillet tables

Coosa: decking replacement, transoms, sun decks, and bulkheads

Starlite: internal components such as drawer bottoms and upholstery substrates

Teak: hatches, doors, and accent pieces

Expanded PVC: small or medium sized upholstery substrate

Acrylic: dash panels, console and cabin doors, windshields

King Starboard Anti-Skid: steps, swim platforms, deck storage lids

EVA Foam: decking, helm pads, coaming pads, and swim platforms

Solid Surface: countertops, vanities, and wet bars