Understanding Bilge Pumps

June 01, 2023 10 min read

Like many pieces of safety equipment, bilge pumps simply don’t get the attention they deserve. Having the right bilge pump with the right features, and knowing how to properly use it, is critical to protecting your boat, equipment and passengers.

Contents

- 1. Bilge Pump Basics

- 2. Automatic vs. Manual pumps

- 3. Types of Automatic Bilge Pumps

- 3.1 Hinged Float Switch:

- 3.2 Ball Float Switch:

- 3.3 Water Sensors:

- 4. Bilge Pump Wiring, Switch Position and Use

- 5. Inspecting and Testing Your Pump

- 6. Pump Size

- 7. Back-up Pumps

- 8. Additional Tips

- 8.1 Leave Your Pump on the Auto Setting

- 8.2 Do Not Leave Your Pump in the Manual “on” Setting All Day

- 8.3 Flip Your Pump on Regularly if You Don’t Have a Float Switch

- 8.4 Check Your Bilge Manually At Least a Few Times A Day

- 8.5 It Takes a Fair Amount of Water in the Bilge Before Most Float Switches Will Turn Your Pump on

- 8.6 Run Your Bilge Pump While Getting on Plane

- 8.7 Learn Your Boat’s Bilge Habits

Bilge Pump Basics

Even a small amount of water in the bilge of a boat can cause serious issues. Standing water on raw fiberglass can make it brittle over time, and many “wood-free boats” use foam filled stringers that can become saturated, heavy and weak if constantly submerged. Wiring and electrical connections will corrode quickly, impacting electronics, pumps, lights and even the electrical systems related to your engine. A properly installed and operated bilge pump will keep your bilge dry and your boat in good working order.

Although often small and installed out of sight, bilge pumps are installed in most boats to expel water that collects in the bottom of a boat (the “bilge”). Bilge pumps should always sit in the lowest part of the bilge when the boat is at rest. If possible, they should be installed in an easily accessible location so that you can frequently inspect, clean out, test and, if necessary, replace them.

Automatic vs. Manual pumps

Boats with open bilges, such as john boats or smaller skiffs without liners may only need a simple, manual pump turned on or off by the operator via a two position (on/off) switch. Boats with partially or fully enclosed bilge areas should have an automatic bilge pump to expel water when it may not be visible. Automatic pumps typically use some kind of float switch or water sensor, which will turn the pump on when the water level in the bilge reaches a certain point.

Types of Automatic Bilge Pumps

While manual bilge pumps operate from a console or accessory panel switch, automatic bilge pumps generally have two switches that activate them — one on the console or accessory panel and a separate switch or sensor on the pump itself to activate and deactivate the pump based on the water level in the bilge. These bilge pumps use different mechanisms to activate them when left in automatic mode:

Hinged Float Switch:

The most common design uses a hinged, floating arm attached to the pump housing. This arm floats up when there is water in the bilge, activating the pump, and, as the water level drops, turns the pump off again.

Ball Float Switch:

Another common design are bilge pumps that incorporate a floating ball into the pump housing. As the water rises, the ball floats up, eventually activating a switch that turns on the pump. This style uses less space in the bilge than a hinged float switch.

Water Sensors:

Some automatic pumps use sensors instead of mechanical switches to activate the pump. Like ball float switch pumps, these pumps typically have smaller dimensions and work well for tighter spaces. Some of these have built-in buttons to test the pump to ensure it is working properly.

Bilge Pump Wiring, Switch Position and Use

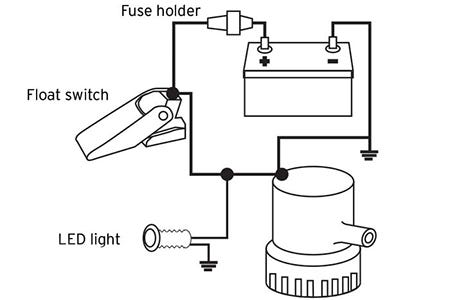

Both manual and automatic bilge pumps are typically wired through a main switch located on the console or accessory panel on the boat. Depending on whether your bilge pump is automatic or not, your switch will either be a two-position switch (manual pump) or a three-position switch (automatic pump).

For manual pumps, the switch simply turns the pump on or off and relies on the operator to know when to turn it on, and to remember to turn it off when the bilge is dry. Many a battery has been drained — and many a pump burned out — because the boat owner forgot that their quiet little bilge pump was still running.

Automatic pumps require a three-position switch, enabling the pump to be turned on manually, turned off completely, or left in automatic mode. It’s important to know which switch position puts the pump in automatic mode, as this can vary based on how the switch was wired. Once identified, the “automatic” switch position should be clearly labeled and should generally be the default position used.

Automatic bilge pumps should only be turned off in rare cases, such as when you are fishing skinny water in “stealth mode” and don’t want the bilge pump to suddenly activate and scare fish away. The “off” position may also be used in cases where the automatic sensor or switch on the pump fails and leaves the pump running.

Inspecting and Testing Your Pump

Keeping your bilge clean ensures your pump works when you need it to. Check around your bilge pump for debris such as old electrical tape, lures, bits of fishing line, sticks, leaves, etc. that often collect in the bilge. This debris can clog the pump intake, reducing or eliminating the pump’s suction. It can also interfere with your automatic pump mechanism.

In addition to removing debris, inspect the pump itself and the automatic mechanism or sensors for corrosion or oily residue that may reduce their effectiveness.It is also extremely important to test your bilge pump frequently. For manual pumps, this can be as simple as flipping on the switch and listening for the pump to turn on, but it is important to ensure the pump will move water.

Automatic pumps require both testing the pump via the console or panel switch as well as testing the switch or sensor on the pump itself. When in automatic mode, your pump should turn on within 10 seconds (but ideally less) and should pour a solid stream of water out. Installing your bilge pump in an easily accessible location makes frequent inspection and testing much easier.

Pump Size

Making sure your pump is operating correctly is only one piece of the equation. You also need to ensure that your pump has the right capacity for emergencies. If your bilge pump cannot pump more water out than is coming in, it is only delaying an inevitable outcome. There is a standard rule for bilge pump minimum capacity: the number of gallons your bilge pump can pump per hour (GPH) should be at least thirty-five times (or more) the length of your boat. So, a 20-foot boat should have a bilge pump with a minimum capacity of 700 GPH.

Keep in mind that bilge pumps rarely pump their rated capacity in the real world. The rated capacity is the amount of water the pump can move under ideal conditions. More “head” (the vertical distance the pump must lift the water to the outlet), longer and/or smaller diameter, outlet hoses and debris in the pump and/or hose all reduce real-world capacity. If space and power source allow, bigger is generally better.

The number of gallons your bilge pump can pump per hour should be at least thirty-five times the length of your boat.

Back-up Pumps

They say trouble comes in threes, and when a boat takes on water, things can go wrong quickly. Larger boats often have multiple bilge pumps, each wired separately to the power source. Installing cartridge-style pumps with spare cartridges on-board can make for quick replacement on the water should your primary pump fail. However, even when all safety precautions are taken, pump failures can still occur. Regardless of your bilge pump system, it is important to always have a truly manual backup option, such as a high-capacity hand-operated pump and a large bucket easily accessible in your boat.

All boats operate on a simple principle: Keep water on the outside of the hull. As simple as that seems, nature and time are constantly working against you. Choppy conditions, leaky through-hulls and plumbing failures are common realities you need to be prepared for. While a solid hull and good boatmanship can go a long way towards keeping water out, your bilge pump is an unsung hero, quietly putting the water that does get in back where it belongs. Taking time to understand your pump system, use it properly and maintain it will keep your boat and its occupants out of harm’s way.

Additional Tips

Bilge pumps are pretty simple devices; they’re either running or they’re not. So what could be complicated about using them? Not much, really, but there a few tips and tricks that can improve safety and utility:

Leave your Pump On the Auto Setting

Whether you have a separate float switch or an integrated one, the “auto” setting on your panel switch means that the pump will come on whenever the water in your bilge rises above a certain level. For normal operation, just leave the switch there and your bilge water level should largely take care of itself.

Do Not Leave your Pump In the Manual “on” Setting All Day

Bilge pumps don’t draw a large amount of current, but combined with audio systems, electronics, livewell pumps, etc. they can kill batteries. Running a pump continuously can also shorten its service life. One way to avoid accidentally leaving your pump on under normal conditions is to keep your finger on the panel switch until you’re ready to turn the pump back to auto or off.

Flip Your Pump On Regularly If you Don’t Have A Float Switch

Without a float switch, you’ll want to make a habit of flipping your pump on periodically to empty your bilge and at the same time check to make sure you don’t have an abnormal amount of water coming into the boat. Most boats naturally accumulate some water in the bilge, so seeing a few cups shoot out every few hours usually isn’t cause for concern. Then, as mentioned above, switch your pump back off.

Check your Bilge Manually At Least A Few Times A Day

It’s easy to forget about your bilge water level with an automatic pump. But float switches can and do fail, allowing water to accumulate. Blown fuses and failed wiring connections can also keep switches and pumps from functioning normally. A few times a day, flip your pump on manually to make sure you don’t have an unusually large amount of water in the bilge.

Float switches can also stick in the “on” position so that the pump keeps running even after the water level has dropped. If you manually flip your pump on and don’t see any water coming out, it means one of three things:

- Your boat has a really dry bilge.

- Your float switch is stuck on and your pump is running continuously, keeping your bilge dry.

- Your pump itself isn’t working and water is accumulating in your bilge.

If it’s A, great! If it’s B or C, you’ll need to diagnose and fix the problem.

It Takes A Fair Amount of Water in the Bilge Before Most Float Switches Will Turn your Pump On

In order to prevent frequent “cycling” on and off, float switches are normally designed and installed so that they don’t activate your bilge pump until there’s a significant amount of water present. In other words, you can keep your bilge significantly dryer by manually switching your pump on every hour or so than by waiting until enough water accumulates for the float switch to turn the pump on.

Run Your Bilge Pump While Getting on Plane

As your bow rises and your boat climbs out of the hole, bilge water naturally runs aft pooling at the transom. This allows your bilge pump to get rid of the maximum amount of water.

Learn Your Boat’s Bilge Habits

A big part of managing bilge water is simply learning what’s normal and what’s not for your particular boat. Some boats have very dry bilges; even a cup of water at the end of the day might be cause for concern. Others might collect several gallons a day or more. That’s not necessarily cause for concern as long as it stays consistent. Over time, you’ll start to see patterns. Do you have more water in your bilge when you run your livewell, for example? When you anchor and fish with several people near the back of the boat? Regardless, what you’re watching for is something unusual that might indicate a dangerous issue.