Bilge Pumps

Bilge pumps remove water that finds its way into your boat’s bilge via spray, rain, small leaks in plumbing or through-hull fittings, and other sources. » Read More

Learn More About Bilge Pumps

Contents

Bilge Pump Basics

All boats inevitably will end up having water that needs to be removed. Water may enter the boat by ice from a cooler, an overflowing livewell, leaking seals around the plug or lights, rainwater, or other sources. When water is left to accumulate in the boat and bilge area this can have unintended and undesirable consequences for one’s boat. For example: destabilizing the boat, formation of osmotic blisters in the gelcoat of a fiberglass boat, or even the boat eventually sinking. Read More

Bilge Pump Types

Whether you're seeking simplicity, reliability, or advanced functionality, there's a bilge pump type tailored to meet your requirements. Let's dive in and explore the diverse array of bilge pump options to help you make the best choice for your marine adventures. Read More

Considerations for Capacity & Flow Rate

When selecting a bilge pump for your boat, several considerations regarding capacity and flow rate play a crucial role in ensuring effective water removal and maintaining safety onboard. Read More

How Much Water Can a Bilge Pump Move?

These factors collectively influence the pump's ability to move water effectively, emphasizing the importance of selecting the right pump size to compensate for potential losses in efficiency. Read More

These factors collectively influence the pump's ability to move water effectively, emphasizing the importance of selecting the right pump size to compensate for potential losses in efficiency.

Voltage Drop

Most bilge pumps are rated at power levels higher than a boat electrical system will deliver, and the gallons per hour rating is based on that higher power rating. Batteries can deliver optimal power levels when they are being actively charged through shore power or when the engine is running.

However, when not actively charging, the voltage delivered by the battery can decrease significantly. Furthermore, corroded or undersized wires can limit the voltage given to the bilge pump, decreasing the capacity even more.

Vertical Climb

Bilge pumps are also rated when pumping water horizontally. Bilge pumps are located in the bilge, the lowest part of the boat below the waterline. Water will be pumped to reach the outlet above the waterline. All bilge pumps will have to lift the water up some vertical climb, and this significantly impacts the efficiency and capacity of the bilge pump.

Typically, this will cut down the capacity of the pump by 20-40%. If you’re looking to reach a capacity mark, be sure to up the size of the pump to make up for the loss in efficiency.

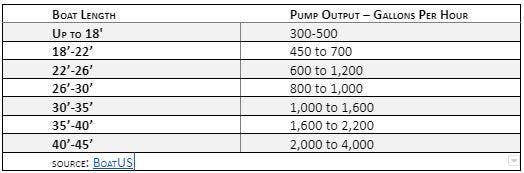

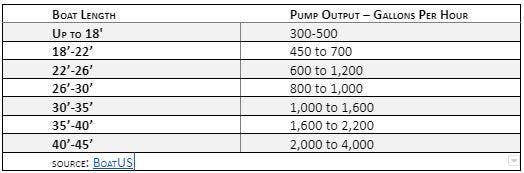

Recommended Minimal Bilge Pump Size by Boat Length

Float Switch Types

When using an electrical bilge pump, the two most common types of bilge switches to enable electrical pumps to function automatically are the built-in automatic switch or a separate float switch: Read More

Replacing an Existing Pump

When replacing an existing pump, it is easiest to match the hose diameter, wiring requirements, and thru-hull fitting sizes to ensure the easiest replacement and installation. This will minimize the need for modifications to the boat or hull.

If you would like to install a higher capacity pump, then you will likely need to update your wiring size, thru-hull fitting, and hoses to match the new requirements of the larger pump size. For an existing installation, it is recommended to find the largest pump that will still be compatible with the existing system. Read More

Plumbing and Installation Considerations

Bilge pump installation requires careful consideration of several factors beyond hose length and type. Placement of the pump within the bilge area, accessibility for maintenance, and ensuring proper drainage are all crucial elements. Read More

Causes of Bilge Pump Failure and Maintenance

Bilge pump failure can occur due to various reasons, often leading to potentially hazardous situations on board. Read More

Final Considerations

Bilge pumps are crucial for maintaining a safe and dry bilge area on boats. They remove the unwanted and sometimes unexpected water that can lead to issues with the function of the boat or even swamping and sinking. As discussed, the most important factors when choosing a bilge pump are the boat’s size, common use cases, and bilge area and swamp capacity.

Proper consideration should be given to the plumbing and installation of bilge pumps and opting to install without understanding the possible implications can be catastrophic to the reliability of the system, electronics, and life of the boat. Read More