- Home

- Maintenance

- Flooring

Marine Flooring

Boat flooring has a tough job description: stand up to punishing UV rays, serious wear and tear, and frequent exposure to mud, fish blood and even oily chemicals; provide secure, slip-resistant footing; and look good doing it. » Read More

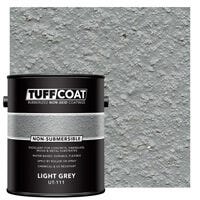

Deck Paint

Vinyl Flooring

Learn More About Marine Flooring

Contents

Boat Flooring: Foam and Vinyl

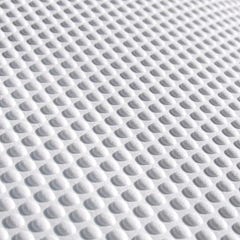

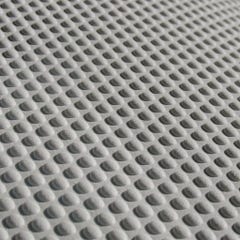

Aftermarket boat flooring made from closed-cell foam or vinyl is a popular option for boat owners who want a comfortable, attractive and durable surface to walk on. Vinyl and foam boat flooring are available in a wide variety of colors, thicknesses and patterns, allowing boat owners to achieve a unique and personalized look for their vessel.

The most popular materials — EVA foam, PE foam, and blends of the two — are closed-cell foam materials that are known for their durability, non-slip surface and ability to withstand harsh marine environments. They are also a lightweight and flexible material that can be cut and shaped to fit a variety of boat deck configurations. Read More

For heavier duty applications like engine rooms, galleys, cold-water fishing boat decks and commercial use, vinyl flooring such as Loncoin, Lonmarine and Lonplate sheeting offer superior toughness and ease of maintenance but without the soft touch and cushioning of foam.

Closed Cell Foam for Boat Flooring

The closed cell foam used in boat flooring is a very different material from what you might normally think of as foam. For starters, it’s highly resistant to staining, for several reasons: Read More

Hydrophobic properties — Closed cell foam is hydrophobic, meaning that it repels water and other liquids. This property helps prevent liquids from seeping into the foam, making it much less likely to stain.

Durability of surface — Closed cell foam has a durable surface that is resistant to abrasions, scratches, and other forms of wear and tear. This makes it an ideal choice for high-traffic areas where spills and stains are likely to occur.

Resilient material — Closed cell foam is a resilient material that returns to its original shape after being compressed or impacted. This resilience helps the foam resist damage and makes it less likely to become stained.

Easy cleaning — In the event of a spill or stain, closed cell foam is easy to clean and maintain. Simply wipe the surface with a damp cloth, and the stain will often come right out.

UV resistance — Many closed-cell foam products are UV resistant, meaning that they will not fade or deteriorate when exposed to sunlight. This makes them an ideal choice for use in boats, where they will be exposed to UV rays on a regular basis.

Closed cell foam is an excellent choice for boat flooring and cushioning due to its excellent stain resistance. With its hydrophobic properties, durable surface, resilience, easy-to-clean nature, and UV resistance, closed cell foam is the ideal material for boat owners who want to protect their investments and maintain the appearance of their boats. Whether you're looking for a soft, comfortable surface to stand on or a material that will keep your boat looking its best, closed cell foam is an excellent choice.

Advantages of Foam Decking on Boats

Adding boat flooring made of EVA or PE foam provides a number of advantages over the nonskid surface that covers the floor or deck of most boats. On fiberglass boats, nonskid usually consists of either a pattern molded into the surface of the deck or of gritty, sand-like material mixed with paint or gel coat and then sprayed onto the deck. On aluminum boats, nonskid is usually applied as a self-adhesive sheet with a gritty surface, much like you might see on concrete or metal stairs. Read More

- Comfort: One of the primary advantages of foam decking over nonskid is the level of comfort it provides. The cushioned surface is gentle on the feet, making it ideal for long trips on the water. Nonskid decking isn’t cushioned at all and is less comfortable to walk or stand on, especially for extended periods of time

- Insulation: Foam decking provides excellent insulation, helping to keep the boat's interior cool in hot weather and warm in cold weather. Boat flooring made of closed-cell foam also resists getting hot in the sun, even in darker colors. Nonskid decking does not provide insulation, and the surface may become hot or cold to the touch, making it less comfortable to walk on.

- Light weight: Foam decking is lightweight, making it easy to handle and install. This is especially beneficial for smaller boats that may not be able to handle the weight of heavier flooring options

- Easy to clean: Foam decking is easy to clean and maintain, as it does not absorb water or stains like some other flooring materials. In fact, gelcoat is somewhat porous and if not carefully maintained can absorb stains. Nonskid decking can also be more difficult to clean and may require specialized cleaning products to maintain its appearance.

Some Considerations of Foam Boat Flooring

As with everything on boats, there are tradeoffs with marine foam decking. Although it is attractive, cushiony and soft to the touch, it does have some drawbacks when compared to traditional nonskid. Read More

Durability: Foam decking can be prone to damage from sharp objects, such as fishhooks, knives, and gaffs, and may be more likely to show wear as compared to nonskid. Nonskid decking is typically more durable and less prone to damage.

Slip-resistance: Foam decking is slip-resistant; however, it’s not as slip-resistant as most types of traditional marine nonskid decking. This may be a concern for boat owners with traction at the top of their “must haves” list.

Lifespan: The amount of time before any type of boat flooring becomes worn varies widely with how heavily it’s used, how well it’s maintained, where and how the boat is stored, the climate and many other factors. That being said, most manufacturers of foam boat deck material say their products should last roughly five to 10 years before they need to be replaced. Most types of nonskid decking can be expected to last longer than that.

Removal: Foam boat flooring sticks in place with a powerful adhesive. If properly installed, it can be quite difficult to remove and usually leaves some residue behind. That’s not a problem if you want to replace your old foam boat flooring with new foam flooring. But if you want to go back to traditional nonskid, getting rid of all the residue from the adhesive takes a combination of chemicals and elbow grease.

Uses of Foam Decking

Foam decking is used for a variety of applications on boats, from small pieces like cooler toppers and helm pads to whole-boat applications. It is often used to replace the original decking on boats, or as an additional layer over existing flooring. Foam decking is also great to cover up those ugly nonskid areas where a repair was completed, but not fully hidden, or the nonskid has become damaged or stained over the years. Foam decking can bring a new vibrance to your boat! Read More

Marine foam flooring can also be used to provide additional insulation from sound and is great for those fishermen looking to sneak up on schools of redfish in the shallows and especially helps to reduce noise and vibrations, also making it ideal for use on yachts where noise reduction is important for the comfort and enjoyment of passengers and crew. It will also improve the look and feel of the boat's interior and enhance the overall feeling of comfort and safety of the boat. It also provides a comfortable area to sit or lay out in contrast to the typically rough marine nonskid that comes standard on most boats.

Some other common uses of foam decking are in the form of helm pads, cooler toppers, center console dash covers, and flooring for poling platforms and casting platforms on flats skiffs. These smaller pieces of foam decking offer a range of benefits and can easily be added to most boats to provide extra comfort, functionality or even hide some old screw holes from accessories!

Helm pads are a popular use for foam decking, as they provide a comfortable surface for the captain to stand on while operating the boat. If you’ve ever been barefoot on a boat for extended periods, then this can be a lifesaver. This type of foam flooring is usually made of high-density foam that is both durable and shock-absorbing, which helps to reduce fatigue during long periods of operation. The foam is also designed to be non-slip, so it provides a stable surface to stand on even in wet conditions.

Cooler toppers or cooler seat pads that are made from foam decking can also be a great addition to any boat. They provide a comfortable, cushioned place to sit, as well as a place to store drinks and snacks. On flats skiffs where coolers are sometimes used as casting platforms, an EVA foam cooler topper provides both cushioning and traction.

Center console dash mats made from foam decking are another popular accessory for boats. These mats are designed to fit the dimensions of a boat’s dashboard, the top of the console, the glovebox or even inside the center console. They can provide a non-slip, padded surface for handheld electronics or help to hide imperfections that come over years of ownership. The dash mats are typically made of durable, marine-grade foam as well.

Marine EVA flooring material can even be used for coaming pads or coaming bolsters. Adhering thick strips of EVA to the insides of your gunwales for padding is much easier and much less expensive than having traditional upholstered coaming bolsters made and installed.

Foam decking is a versatile and useful material for boat owners looking to enhance their boating experience. Helm pads, cooler toppers and center console dash mats in addition to whole boat flooring installations made from foam decking provide a good-looking, comfortable, non-slip, and durable solution for various applications on boats. These pieces of foam decking, both large and small, can be easily added to most boats and offer a range of benefits that are sure to make any boating experience more enjoyable.

Installation Considerations

Getting the results you want from foam marine flooring has a lot to do with the quality of your prep work and installation. Read More

- Clean surface: The surface where the foam decking will be installed must be clean and free of debris to ensure proper adhesion. This will also help to prevent air bubbles from forming under the foam.

- Proper measurements: It is essential to take accurate measurements of the surface where the foam decking will be installed to ensure a proper fit; as the old carpentry adage goes, “measure thrice, check twice, and cut once.” Measuring the surface before cutting the foam will help to minimize waste and ensure that the foam fits correctly. There is also the option to have your boat professionally measured and the foam installed by a pro, thus ensuring that the dimensions are as close to perfect as possible.

- Adhesion: The foam decking must be properly adhered to the surface to prevent it from shifting or becoming detached. Most foam deck materials employ a high-tech, pressure-activated “peel-and-stick” adhesive. Significant pressure is required to make the adhesive stick. It’s also best to let the adhesive cure for 24 to 48 hours before using your boat. Note that these adhesives are meant to be semi-permanent to permanent and will typically leave a residue upon removal of the decking.

- Sealing the edges: To prevent water from entering under the foam decking, it is important to seal the edges where the foam meets the boat's hull. This can be done with a marine-grade sealant, and it is essential to follow the manufacturer's instructions for proper application. This is one of the biggest complaints from boat owners, seeing the edges peeling and ultimately water intrusion underneath the decking. This can lead to the decking failing and completely peeling away from the deck.

Vinyl Boat Flooring

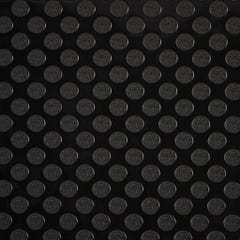

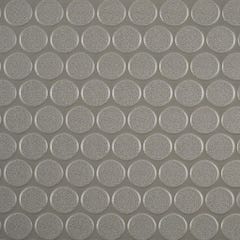

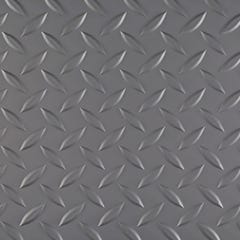

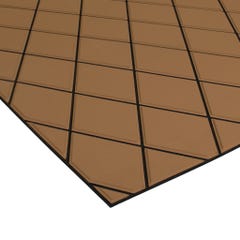

An alternative to popular foam boat flooring products like SeaDek, MarineMat, DEKit, AquaTraction and others is vinyl boat flooring. Vinyl flooring lacks the cushioned feel and soft-to-the-touch surface of foam decking, but it’s less susceptible to cuts and punctures, virtually impervious to stains and very easy to maintain. Vinyl boat flooring also tends to be less expensive than foam decking. On the other hand, vinyl is more challenging to install than most foam decking, since a separate epoxy adhesive and heavy rolling tools are required. Read More

Vinyl boat flooring is available in a variety of textures, finishes and colors, ranging from utilitarian, commercial-grade materials to accurate imitations of wood, including the traditional teak-and-holly flooring found on classic boats.

Contact Us

If you’re having trouble finding the exact part you're looking for, the best first step is to take a picture and give us a call.

Our customer service team is here Mon-Fri 8am - 5pm and would love to help you track down the exact hardware you need.

Need Help?

Speak to one of our industry pros:

Tap to Call

Commonly Asked Questions About Marine Grade Flooring

Foam decking on boats refers to the use of foam material, such as EVA (ethylene vinyl acetate), as a deck covering for boats. The foam provides a soft, cushioned surface that can improve the safety, comfort, and soundproofing of the boat.

Foam decking is used on boats for several reasons, including increased safety, improved comfort, and better insulation and soundproofing. The foam provides a non-slip surface that reduces the risk of falls and other accidents, and it can also absorb noise and vibrations to create a quieter and more comfortable ride.

Foam decking is typically installed on boats by adhering it to the deck surface. The foam can be cut to fit the specific contours and features of the boat deck, and it is then glued or secured in place using adhesives or other fastening methods.

Vinyl decking on boats refers to the use of vinyl material as a deck covering for boats. Vinyl is a durable, flexible, and low-maintenance material that is often used as an alternative to traditional decking materials, such as wood or composites.

Vinyl decking is used on boats for several reasons, including its durability, ease of maintenance, and non-slip surface. Unlike some other decking materials, vinyl does not rot, splinter, or fade, and it is easy to clean and maintain. Additionally, vinyl decking often has a textured surface that provides good traction and reduces the risk of slips and falls.

Vinyl decking is typically installed on boats by rolling it out over the deck surface and securing it in place using adhesives, fasteners, or a combination of both. The vinyl can be cut to fit the specific contours and features of the boat deck, and it is then secured in place to create a seamless, waterproof surface.