- Home

- Material

- Plastic Sheet

- King Starboard

King Starboard

The leading marine-grade plastic sheet material, King Starboard is impervious to UV and moisture so it will never fade, rot or delaminate, yet requires no special tools or skills to fabricate with. » Read More

Shop By Color

Unsure on Color?

We offer a wide array of colors to match the most common boat gel coats and marine colors schemes. Explore the color options and guarantee a perfect match with a sample chain.

Shop Specialty Starboard Shapes

As the world’s leading fabricator of King Starboard, we can cut or fabricate virtually anything to your specifications. For popular shapes we offer self-service "build-your-own" options below.

Need a Custom Shape?

Need a unique part or can’t find the replacement item you’re looking for? We do custom projects every day for our customers! Contact our Design & Engineering team to start a custom cut or unique project.

Learn More About King Starboard

Contents

What is King Starboard

Revered for its versatility, and durability, King Starboard is the most popular plastic sheet material used in the marine industry. It is composed of High Density Polyethylene (HDPE) and infused with UV inhibitors, meaning it can never rot, delaminate or fade. Starboard comes in a variety of colors with a textured surface that hides minor scratches and offers some amount of non-skid.

Benefits of King Starboard

King Starboard is relied on to withstand the harshest outdoor conditions because it’s incredibly strong, durable, and long lasting. Unlike teak and other woods, starboard doesn't need regular maintenance and will never delaminate or disintegrate when exposed to UV, humidity or water. Additionally, King Starboard is very easy to work with and can be fabricated with standard woodworking tools. These unique qualities combined with a wide selection of colors and a visually pleasing matte finish make starboard a great option for countless projects.

What We Do With King Starboard

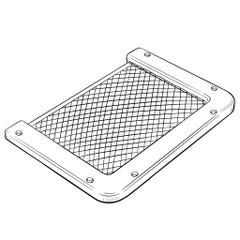

As the world's leading fabricator of King Starboard we pride ourselves on our experience and knowledge of this versatile material. King Starboard has become the industry standard for the fabrication of tackle boxes, rod holders, access doors, filet tables, tool holders, and a wide variety of other marine products.

Beyond marine, King Starboard is an ideal material for the construction of anything that requires long-term weather resistance. We've supplied starboard for everything from custom outdoor furniture, art installations, and even animal enclosures for a national zoo.

The Ultimate Guide to Working with King Starboard

Learn from over 30 years of fabrication experience the tips and tricks for working with King Starboard using only conventional woodworking tools.

Limitations of Starboard

Although starboard has many advantages, working with the material does present a few limitations to consider. Due to its compositions, the material:

- Cannot be painted

- Cannot be sanded

- Cannot be glued

- Must be supported when spanning large distances

Alternatives to Starboard

There are some projects where starboard is not your best option. For example, Coosa Board is better for transoms and decks due to its rigidity and comparably lighter weight. Similarly, some customers prefer accessories with a high-gloss finish that matches the boat's gel coat. For these customers, acrylic is the better choice.

Lastly, for applications where the material will be visually hidden (upholstery substrate for example), using Starboard would be unnecessarily expensive and lower cost Expanded PVC is a better value option.

How to order

We purchase and fabricate more starboard than anyone else in the world (over 76,000 sheets in 2020!). This high volume allows us to accommodate any order, large or small, with fast lead times and low prices. Custom cuts and full sheets are available 24/7 at Boatoutfitters.com, if you need help placing an order or have any questions we have a team of experts here to help.

Contact Us

If you’re having trouble finding the exact part you're looking for, the best first step is to take a picture and give us a call.

Our customer service team is here Mon-Fri 8am - 5pm and would love to help you track down the exact hardware you need.

Need Help?

Speak to one of our industry pros:

Tap to Call

Commonly Asked Questions About King Starboard

Starboard is a thermoplastic sheet composed of High Density Poly Ethylene (HDPE) and infused with UV inhibitors, to create a virtually indestructible plastic sheet.

The strength of starboard depends on its size and thickness. Starboard is easily strong enough to be used for hatch lids, and swim platforms but it must be supported properly. The actual tensile strength of starboard at yield is over than 4,100 PSI.

King starboard does float. However, starboard is not overly buoyant, it will support its own weight when submerged but a minor amount of additional weight will make it sink.

One of the best things about starboard is that it's maintenance free. Starboard never needs to be polished or refinished and is easy to clean. Dish soap, citrus cleaners, alcohol, mineral spirits or a magic erasers are all good options for cleaning Starboard.

Starboard is easily fabricated using standard woodworking tools such as table saws, routers and sanders.

Starboard is easily fabricated using standard woodworking tools such as table saws, routers and sanders.

Starboard can not be painted, there are no paints, dyes, or stains that will hold to the material for any significant amount of time. Not being able to paint starboard is not a common issue due to all the available color options.

King Starboard can not be glued, it has to be assembled using stainless fasteners or plastic welding rods. Some adhesives claim to bond starboard, but none offer permanent adhesion. Caulks like Elastomeric Marine Sealant can be used with starboard to seal seams but must be used in addition to screws or bolts.

Starboard takes a long time to heat to a formable temperature and does not hold its shape well once cooled. If you need a plastic sheet that can be heat shaped or molded, acrylic is a better option.

Like all thermoplastic sheets, King Starboard has limited stiffness. Starboard will bend if not properly supported. For example, If you lean a large sheet against a wall at an angle the material can sag over time, especially in the heat.

King Starboard will never fade or discolor. The color is consistent all the way through the plastic sheet and special UV inhibitors protect it from the sun to eliminate fading.

Adhesive backed high density foam materials are commonly used on starboard, however, a permanent adhesion can not be guaranteed.

A full 48” by 96” sheet of ½” king starboard weighs roughly 80lbs, making it about twice as dense as standard plywood.