Plastic Sheets

The modern boat builder and DIY boat owner has a wealth of high-quality marine plastic sheets to choose from. When choosing the best-suited marine plastic board, there are many factors to take into consideration. » Read More

Learn More About Marine Plastic Sheets

Contents

Why Marine Plastic?

Modern marine plastics are specifically formulated for use in high-stress saltwater environments. These plastics will not rot, swell, delaminate, or discolor when exposed to UV, water, or humidity. There is a marine plastic sheet to fill every job.

Types of Marine Plastic Sheets

When it comes to marine plastic sheets, there's a wide range of options to suit every need. With these options, you can find the right marine plastic sheet for your needs. Read More

King Starboard

The most popular marine grade plastic sheets are made of King Starboard HDPE material, also known as marine HDPE board, marine poly board, and marine polymer board. King Starboard is impervious to UV and moisture so it will never fade, rot, or delaminate. Is made of High-Density Polyethylene (HDPE) and is specifically formulated for a lifetime of marine use. HDPE marine board sheet is perfect for use in most marine applications.

Common uses of marine-grade HDPE include but are not limited to, tackle boxes, rod holders, access doors, fillet tables, tool holders, and a wide variety of other marine products. Starboard is not limited to marine use and excels in all applications where weather-resistant plastic sheet material is needed. It is easy to work with using standard woodworking tools.

King Starboard AS

With all the notable features and benefits of classic King Starboard and an added nonskid finish, King Starboard AS (Anti-Skid) marine board is an ideal plastic boat flooring for high foot traffic areas. Starboard AS is perfect for swim decks, hatches, steps, and anywhere traction is a necessity. These nonskid marine grade HDPE sheets are available in two patterns.

The most popular AS pattern is the dot pattern. Dot pattern Starboard AS is available in three colors and two thicknesses. King Starboard Anti-Skid is also available in a diamond pattern. Note that the diamond pattern has grain direction, and you will need to indicate which direction the diamond needs to run. This grain orientation can affect sheet layout, yield, and price.

King Starlite

Looking for the benefits of classic King Starboard HDPE sheet material but trying to reduce weight and cost? King Starlite is extruded with a blowing agent that allows the material to hold air. As a result, King Starlite is 30% lighter than classic Starboard and is considerably more cost-effective. The drawback is that because Starlite plastic marine board has a cellular edge, it can collect dirt and is more difficult to keep clean. It is best used in behind-the-scenes applications where a lightweight budget-friendly plastic is perfectly suited.

Common uses of King Starlite include seat substrates, tackle box interiors, backing plates and paneling, and any application with a hidden edge. Like all King marine grade board products, Starlite is easily installed with common woodworking tools and practices and is built to last a lifetime.

Marine Acrylic Sheets

With a high gloss finish and transparent nature, marine acrylic (also known as plexiglass) is a cost-effective and practical marine sheet for many uses on your boat. Marine Acrylic can be heat-formed and is perfectly suited for boat windshields, dash panels, windows, trim plates, live well lids, console doors, or any other area where a clear or translucent and high gloss finish is wanted.

Acrylic marine plastic is a brittle material and particular care must be taken when cutting and drilling. At Boat Outfitters, we know cutting plexiglass can be stressful and offer custom acrylic cutting based on your specifications.

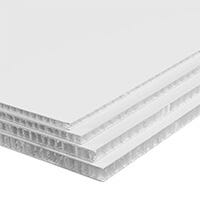

Expanded PVC

If you are looking for a lightweight, smooth marine-grade plastic that is durable and weather-resistant, and economical, Expanded PVC might be the marine sheet for the job. Marine PVC board is the ideal substrate for boat seats, upholstery, and seating bases due to its ease to work with, thermal conductivity, and waterproof nature.

Marine-grade PVC sheeting for boats is easily sanded and cut into any shape you desire. It also has improved color fastness compared to other available PVC products. Because an expanded PVC board is not particularly strong on its own, it benefits from the addition of a backing plate or support system.

EVA Foam Decking

EVA foam boat decking is an ideal material for boat flooring. It is soft, grippy, durable, and stain resistant. Popular brands include SeaDek and Shark Deck.

Coosa Board

Coosa Board is a high-density polyurethane foam with reinforced layers of fiberglass. Due to its composition, Coosa Board is significantly more rigid and lighter than marine plywood. Coosa Board is the premier deck and transom material in the marine industry. Coosa Board is mold and algae-resistant, does not absorb water, and requires no special maintenance or care.

The only drawback to Coosa Board is that it is not UV stable and will fade in the sun. Additionally, it contains fiberglass which can be rough on bare skin. Because of these properties, we recommend covering or coating it in all applications.

Custom Cut-to-Size Plastic Board for Boats

While some marine-grade plastics are easily cut and shaped with standard woodworking tools, others require special techniques and tools. Boat Outfitters offers plastic sheets in a variety of preset sizes as well as custom-cut sizes and shapes to fit your needs.

Custom-cut Starboard HDPE board is available in rectangular sheets up to 54” x 96” (6” wider than a 4’ x 8’ sheet of HDPE board), four thicknesses from 1/4” to 1”, and 10 different colors. Custom cuts can be ordered with a variety of rounded edge styles and your choice of corner radius. Read More

Custom Cut marine acrylic/plexiglass sheeting is available in rectangles with or without polished edges and thicknesses of 1/4”, 3/8”, 1/2”, and 3/4”. Color choices include opaque black, three shades of opaque white, clear, and four shades of tinted translucent. A full sheet of marine acrylic is 4’ x 8’.

Marine-grade expanded PVC sheets are available in white and gray, 1/2”, 1/2”, 3/4”, and 1” thicknesses, and sizes up to a 4 x 8’ full sheet.

Starboard HDPE Rings, Circles, & Frames

In addition to rectangular sheets of marine plastics, we also offer HDPE plastics precut into circles, rings, and frames to your custom dimensions. these shapes are ideal for covering old openings like gauge holes, adding trim around speakers or lights, and adding trim to cover cutouts around electronics.

How do I Order Marine Plastic Sheets?

At Boat Outfitters, we make ordering easy. With cut-to-size options on all major marine plastic sheet materials, ordering has never been easier. Simply select your marine sheet and thickness, and type in your needed dimensions. From there, our team of experts will perfectly cut your marine plastic board. Looking for full-sized plastic sheets? We offer full 48” by 96” sheets in most materials.

Contact Us

If you’re having trouble finding the exact part you're looking for, the best first step is to take a picture and give us a call.

Our customer service team is here Mon-Fri 8am - 5pm and would love to help you track down the exact hardware you need.

Need Help?

Speak to one of our industry pros:

Tap to Call

Commonly Asked Questions About Marine Plastic Sheets

There are several high-end modern marine plastics used in the construction of boats and boat accessories. The most common marine plastic is King Starboard, a high-density polyethylene (HDPE) board that is specially formulated for marine use. Other common marine plastics include acrylic and expanded PVC.

HDPE stands for high-density polyethylene. HDPE is a specially formulated plastic that is perfect for marine use. HDPE marine board does not rot, delaminate, swell, or discolor and is UV stable. HDPE is also used for products like cutting boards, but marine-grade HDPE contains UV inhibitors and other additives that help it stand up to the marine environment.

Marine board refers to commonly used boat-building materials. Most modern marine boards are made from high-quality marine plastic that is built to stand up to years of use in marine environments. Marine board differs from standard board in the fact that marine board does not absorb water and will not delaminate or disintegrate when exposed to humidity and water.

An expanded marine PVC board, or expanded PVC, is a type of PVC that has been expanded with a special foaming agent to increase the thickness of the material while reducing its density. This makes the material lighter while maintaining structural integrity and strength. Because expanded PVC is highly weather-resistant, it is commonly used in building boating accessories.