- Home

- Electrical

- Wiring

Wiring

Wire, connectors, fuses, circuit breakers, panels, buss bars and other marine wiring components are critical to the operation of virtually every recreational boat. » Read More

Learn More About Wiring

Contents

Safety First!

Before we get too deep into this, a few things need to be made clear. Electricity is no joke. On bigger systems it can kill you, and on smaller systems it can certainly wake you up. When rigging up anything electrical, remember “you can’t put the smoke back in the motors.” Once you rig something wrong, you can destroy it at the flip of a switch. The parts you waited on could be ruined just like that. Read More

A simple short on a non-fuse protected circuit can start a fire at sea. Always play it safe with electricity! Disconnect your batteries, make sure your battery switch is off, and don’t be afraid to test everything with your meter before you begin working on it.

Before we get too deep into this, a few things need to be made clear. Electricity is no joke. On bigger systems it can kill you, and on smaller systems it can certainly wake you up. When rigging up anything electrical, remember “you can’t put the smoke back in the motors.” Once you rig something wrong, you can destroy it at the flip of a switch. The parts you waited on could be ruined just like that.

A simple short on a non-fuse protected circuit can start a fire at sea. Always play it safe with electricity! Disconnect your batteries, make sure your battery switch is off, and don’t be afraid to test everything with your meter before you begin working on it.

Marine Wire

Let’s get started with one basic element of wiring — the wire itself. How does marine wire differ from other types of wire? There are a few different ways that marine wire sets itself apart from the others. First off, marine wiring is “tinned.” Tinning is a process in which wire is coated with a compound to resist corrosion. Marine wire also contains more copper than normal wire of the same gauge. This allows for a higher electrical carrying capacity. Furthermore, marine wiring is coated in a PVC jacket that is corrosion resistant. Some marine wiring manufacturers have stepped it up even further by making their wire coating resistant to chemical exposure as well as flame. Read More

In all, marine wiring is built to withstand the brutal conditions that the maritime environment brings. Constant shifting temperatures, constant moisture, and constant jarring make this environment pretty difficult to stand up to. To use a type of wire not meant for marine use could cost you in the long run. Wires that aren’t coated properly could corrode and fail. Do you really want to risk your bilge pump not kicking on just to save a few bucks?

The Very Basics

The very basics of marine boat wiring are pretty simple. For small boats like skiffs and jon boats their entire electrical system might only involve a few parts. The jon boat is one of the most popular boats on many bodies of water today, and its electrical system may only consist of navigation lights and maybe a fishfinder. Read More

If your boat has electric start, you will need cables running to your battery. These will be the largest wires in your boat, typically between 2 and 6 gauge. The gauge is important because too much amperage can cause a small wire to overheat. Most outboards also offer a charging system from the outboard, allowing you to charge your starting battery or power some of your accessory electrical systems. How to wire a boat motor can be as simple as just connecting the motor to a battery, but the more gauges and displays, the more complicated it will get.

Again, on the simple jon boat we’re talking about, the only other wire to consider might be the navigation lights. Wiring boat lights to a switch is one of the most important tasks in simple boat wiring. On navigation lights, the American Boat and Yacht Council recommends using at least 16 gauge wiring, but going larger is a safe bet. Now you just have to pick a switch. There are many options, but it’s best to get a three position switch to have the navigation lights off, on, and just the anchor light on.

After wiring the switch to the battery, and then to the light, it’s important to protect your electronics with an inline fuse. We will go into fuses more, but they’re critical for boat safety and avoiding disaster at sea.

That’s it as far as the simplest jon boat or dinghy is concerned. Obviously there are a million differences between yacht wiring and how to wire a small boat. Basic boat wiring is all relative to the size and application of your boat. Boats built to entertain might not have the same boat electrics as a boat built purely for fishing.

The “Master Switch”

Battery switches can be used as the “master switch” for your boat. They are very heavy gauge switches that allow you to cut power off completely to the boat, or switch between batteries on the boat. Cutting your power off completely allows you to leave your boat with no worry of any power drain, or any potential electrical issue while you’re gone. Being able to switch between batteries means you can run your electronics with the motor off and still have peace of mind that one battery or battery bank is still completely charged. If you choose to use only your accessories, battery switches would allow you to keep your starting batteries charged while you use your house batteries. Read More

The battery switch is important when working on your boat as well. Be sure the switch is OFF before doing any sort of electrical work! It is important to remember that some electrical accessories may need to stay on even when your boat is left unattended. Bilge pumps on float switches should stay turned on in case of heavy rain.

Types of Connectors

There are a few main connectors widely utilized in the marine world, and they all serve their own purpose. The most important of them all is the ring terminal. This is the connection from the wiring to the battery. They attach an electrical cable to a circuit point. Read More

Another common connector is the butt connector. This connection is used to join two wires together. This is also called splicing and can be problematic if done improperly. On marine applications it is critical to use heat shrink connectors, or cover the butt connectors in heat shrink tubing. This ensures a water tight connection. Any water allowed into a connection can cause corrosion, leading to issues down the road.

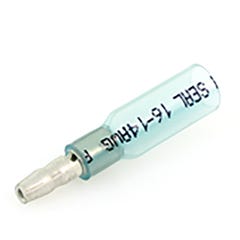

Quick disconnect terminals are a popular terminal for switches and typically smaller connections. They vary from 10 to 22 gauge, unlike ring and butt connectors which are available in much larger sizes.

The spade connector is an open-ended connection. It’s similar to a ring terminal but is advantageous in that it can be attached to a stud without completely removing the nut. Just back off the nut a few turns, slide in the terminal, and tighten. Regardless of the connection, proper crimping and sealing is critical to avoid corrosion.

Fuses and Breakers

Much like in houses and vehicles, boat circuits have to be protected. This is done with fuses or breakers. Fuses are most common in smaller boat applications, or lower amperage applications. Breakers and fuses both accomplish the same purpose of breaking a connection when a circuit is overloaded or short circuited. The difference is that fuses must be replaced when they fail, and breakers can just be manually reset. Read More

Fuses consist of a small conductive filament run between two poles. This filament is designed to melt at the slightest excess over its rated amperage. By melting, it opens up the connection, stopping the flow of electricity. Once a fuse filament melts it is ruined and should be discarded. For this reason it is important to make sure you know what amp and style of fuses your boat uses. Once you identify the fuses your boat uses, it’s important to keep extra on hand in case you blow one.

Circuit breakers use two methods to open a circuit in the event of overloading or short circuiting, and can be reset after!

Fuses can be installed in a circuit in multiple ways. One way is a simple inline fuse. This is the simplest method, but can be difficult to organize and identify in a boat with multiple electronic accessories. The easiest to organize and identify is a fuse block. This is a place for multiple fuses and allows you to keep everything organized and in one place. With all your fuses consolidated into one area it’s easier to label them and track down possible faults.

Some switch panels come with built in fuse protection, allowing for an all in one installation. Regardless of the size of your circuit or the device you’re powering, all small boat electrical systems need to be fuse or breaker protected.

Bus Bars

A bus bar is a conductive metal bar used for power distribution. It has multiple threaded posts for connecting different ring or spade (fork) connections. The bar allows you to consolidate a lot of your low voltage applications in one single circuit and location, cleaning up your boat electrical wiring.

This can be useful to serve as a ground for multiple applications. Instead of having to run multiple small wires through riggings tubes and all of the hassle involved with that, a buss bar will allow you to ground everything off to one heavier gauge wire running to the battery. They are frequently used in boat dash wiring to organize lighter gauge wires and ease in troubleshooting potential issues.

Running Wire

Now that you have your wiring all planned and all the supplies needed, it is time to run some wires! Running the wires through all the nooks and crannies of your rigging tubes is a chore in its own right. The tubing used to organize all these wires is often referred to as a rigging tube or a wiring chase. These tubes usually consist of two- to three- inch plastic tubing that keeps the wiring out of any water in the bilges and secure from rattling around in the bilge. Read More

By the time you are working on any wiring on your boat chances are the rigging tube is already packed with other lines from the factory. This will add a little bit of challenge to your wiring install but can be worked around. When pulling wires it can help to have the wires you are running lubricated to slide past the other wires in the rigging tube. There are specific lubricants designed for this, but regular baby powder can serve the same purpose.

The most helpful thing possible when running wires with little to no rigidity, is to have a line to pull them through with. When removing old wire, be sure to attach your line from the other side. As you pull your old wire out, the line pulls through the tube with it. Once you have your old wire removed, you can attach the new wire to your line and pull your new wire into the boat from the other end! Make sure when attaching the line to your new wire to tape it in the most streamlined shape possible. Tight rigging tubes can make your new wire want to hang up, so the more streamlined your wire setup the better. Electrical tape is perfect for this job, as it is smooth, flexible, and adheres to itself very well.

This part of wiring a boat can be the most frustrating. Stay patient; this is not something to be rushed. On boats with no rigging tube below deck, it is important to make sure your wiring is secured. Stainless steel cushion clamps can be used to secure your wire above any water left in your bilge and will protect your connections from corrosion and jarring below deck. Make sure your wires are not going to rub or chafe with anything before you consider your project done. Chafed wires or lines can cause headaches going forward.

Rigging Flanges

Once you have your wire run below deck, it is important to protect it where it needs to come above deck. Rigging flanges are similar to cable boots. Flanges and seals are most important when wiring an outboard motor, since inboards don’t use them as frequently. They protect both the boat and the wiring where the wiring runs from the deck into the outboard. Without these flanges your fiberglass or metal hull would abrade your wiring every bit of chop you hit, and moisture would be allowed into the exposed coring of your boat. Read More

There are different styles of flanges for different applications. The tubing that covers your wiring and cables also serves the aesthetic purpose of hiding all your wires as one, while also blocking your rigging from UV degradation. Wherever any wire goes above deck, it’s important to make sure that hull intrusion is properly sealed. This protects the structure of your boat from water intrusion as well as your wire from any chafing against your boat. For cleaner looking wiring, try to run all your wires through one single multi-deck seal. Having one properly sealed hull intrusion is a lot easier to maintain than multiple poorly sealed intrusions.

Contact Us

If you’re having trouble finding the exact part you're looking for, the best first step is to take a picture and give us a call.

Our customer service team is here Mon-Fri 8am - 5pm and would love to help you track down the exact hardware you need.

Need Help?

Speak to one of our industry pros:

Tap to Call

Commonly Asked Questions About Marine Wiring

Marine rated wire is the only acceptable wire for boating applications. It offers protection from the elements and is heavier duty than wire for other applications. For both safety and convenience, avoid using any other types of wire for marine applications.

Marine wiring is different in regards to the conditions it is subject to and some of the risks involved. The wire itself is designed to hold up to the abuse, unlike automotive wiring which is not built to be as durable. The risks involve fires at sea, melting your electronics and injury. Also marine wiring is typically run through a rigging tube designed to protect it in the bilge, unlike automotive wiring which may only be restricted in terms of a firewall.

The best way to splice two marine wires together is a properly sized heat-shrink butt connector. Be sure to strip just enough wire to fit into the connector. If you strip too much wire you risk exposing the wire to corrosion. Crimp the wires firmly into each end and test for strength. After this, heat-shrink your connection using indirect heat. Do not roast your connection, and make sure there is no bare wire exposed!

Different applications call for different connections. For a battery post, the ring terminal is the proper connection. Any post style connection will involve ring connections of varying sizes. Quick disconnects are utilized frequently to connect to breakers, fuses and switch boards. Regardless of what connector you use, make sure it is marine grade and properly waterproofed.

For most simple electrical problems, the issue can be tracked to a connection along the circuit. It’s common for screws and bolts to loosen throughout a boat’s life and that will open a circuit. Connections are the weakest link in a circuit and more likely to fail than uncut wire.

As far as gauge size, it all depends on the application. Some low power draw applications such as LED bow lights may only require 16 gauge wire, while the battery starting cables may require between 2 gauge and 6 gauge.