You’ve got some wood trim on your boat that’s just shot, can’t be refinished, needs replacing. Replacement parts can’t be found. What are you going to do? You’re going to order a custom-made replacement!

Wood trim gives boats a beautiful, classic look. But boats have long lives, and wood ages faster than stainless steel, aluminum and fiberglass, requiring regular maintenance and complete refinishing at intervals. Eventually, teak or mahogany (or ipe or iroko) will be too dried out and brittle to be serviceable and will need replacing.

Contents

Replacement Parts

Replacement parts can be challenging to source but thanks to today’s CNC machining technology, getting custom fabricated replacements has never been easier. Plus, when you turn to custom fabrication for part replacement, a new option comes on the table: replacing wood with long-lasting, low-maintenance plastics. Wood step pads, fiddle rails, entry and access doors, swim platforms, thwarts and so on are readily remade in no-maintenance materials that will retain their newly installed look for many seasons on the water.

Boat Outfitters does thousands of custom fabrication jobs a year working with marine lumber, Starboard, acrylic Plexiglas, Coosa panels, Lexan, Corian, and other materials, so there’s a good possibility they have already re-made the part you need. If not, all you need to do is get in touch with Boat Outfitters’ design and engineering team, and then send them the part to be replicated. You may not even need to send the part if photos and dimensions adequately specify the work to be done.

The Process With Boat Outfitters

Working with Boat Outfitters on a custom part project is often a collaborative process of getting everything right before going to fabrication.

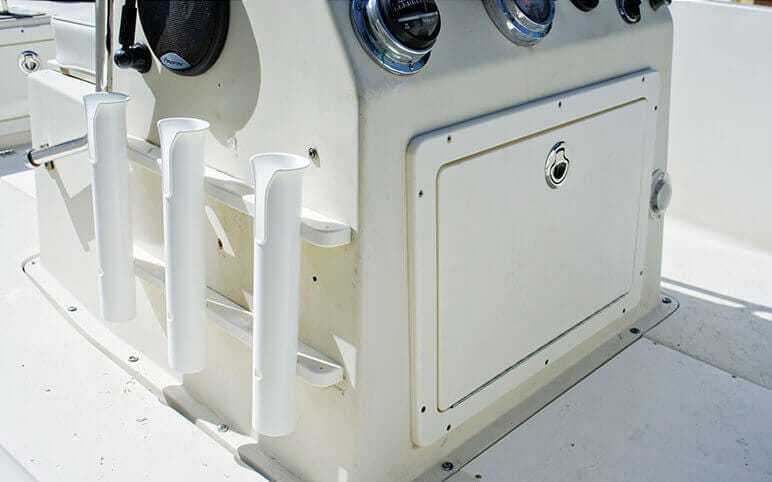

But not always; it can be a lot simpler than that. Some straightforward parts and components can be ordered online simply by inputting dimensions and picking a color. On Boat Outfitters’ Build Your Own page, you can customize a range of ready-to-go projects like access doors, hatches, net holders, storage boxes, or custom-cut EVA foam decking. Enter your dimensions, pick your colors, select from applicable options like latches and door louvers, and off you go; part is delivered, you install it, done. Very off-the-shelf.

Enter your dimensions, pick your colors, select from applicable options like latches and door louvers, and off you go.

Just need something simple like a cleanly machined mounting ring for stereo speakers or a rectangular mounting block? Those can be ordered up in a heartbeat.

More complicated projects will likely require some back and forth with the Boat Outfitters team to ensure everything is correct before cutting starts. Some work with the new part may also be needed on the customer’s end; for instance, if a door latch needs to be fitted to another part, that might be best done by you to get the fit and alignment right. Turnaround time will vary with the complexity of the project.

The Options and the Benefits

The ability to get an otherwise unavailable part made is a boon for boat owners. And if you’re not committed to replacing wood with wood, replacing wood with a synthetic material like Starboard will reduce the maintenance load your boat demands — more time boating, less time fiddling with the boat off the water.

Starboard

King Starboard is a marine-grade high-density polyethylene (HDPE) with added UV inhibitors and stain resistance, manufactured by the King Plastics Corporation. It doesn’t bond with adhesives well, but it does hold screws very well. It can’t be painted, but it comes in several colors, including white, seafoam, dolphin grey, and black. Thicknesses available are 1/4”, 1/2”, 3/4”, 1” and 1-1/2”.

Starboard is easy to work with. No sanding, varnishing or other finishing work is required, and it’s just about as maintenance-free after installation as it gets. Starboard won’t rot, swell, splinter or delaminate from exposure to humidity or water.

Plexiglas Panels

Plexiglas panels are another material that offers benefits, some beyond those attained with Starboard. While Plexiglas is ultimately a more fragile material than nearly indestructible Starboard, and more expensive, with more finishing work required, it has aesthetic advantages (as well as being lighter). It’s available in a wider range of colors, including clear and tinted. It also holds a polish well.

Coosa

Coosa is a one-to-one replacement for marine plywood and is excellent for decking. It’s also an excellent choice for doing custom boat conversions.

In many projects, it will make sense to combine materials. For example, an access door may be framed with Starboard while the door itself can be made from Plexiglas.

Some Limits

There are some limitations in what can be redone on Starboard or Plexiglas because there are things you can do with wood that you just can’t do with HDPE. Some wood parts were originally made by hand and can be time-consuming and prohibitively expensive to duplicate. Weird angle cuts and sanded and tapered surfaces may put a part in this category.

But there are few projects that just can’t be executed, and on the harder projects the limiting factor will be whether you see the part as worth paying for.