What You Need to Know About Replacing Gas Shocks

February 09, 2024 8 min read

Gas shocks — also commonly called gas springs or gas struts — are widely used on boats of all kinds as well as RVs to make heavy hatches and lids easier to lift and hold them in position once they’re open. Like the shocks on your car, though, they don’t last indefinitely. Eventually, you’ll notice that they aren’t quite as strong as they used to be, and at some point, they’ll fail altogether. Fortunately, replacing gas springs and shocks is a simple task. The bigger challenge is finding the correct replacements. Here are 6 tips for finding the right replacement parts for your worn-out gas shocks.

Contents

- 1. Measuring Gas Shock Length

- 1.1 Extended Length

- 1.2 Compressed Length

- 1.3 Throw

- 2. How to Find the Force Rating

- 3. How Much Does Force Rating Matter?

- 4. Gas Shock Brands

- 5. Gas Shock End Fittings

- 6. Black Painted vs. Stainless Steel Gas Shocks

- 7. Removing and Installing Gas Shocks

- 7.1 Cap Style

- 7.2 Slip Style

Measuring Gas Shock Length

The first thing you’ll need to determine when replacing worn-out gas shocks is the length of the old shock. There are actually three different lengths used in gas shock specifications — extended length, compressed length, and stroke.

Extended Length

Extended length is the most important of the three and the first thing to measure. It is measured from the center of one ball socket to the center of the other ball socket with the shock fully extended. Do not measure the overall length of the part, from end to end. Most gas shocks, including all that we sell, are referred to by their extended length. So a “15” gas shock” is a shock with an extended length of 15”.

Compressed Length

Compressed length is the distance from the center of one ball socket to the center of the other ball socket when the shock is fully compressed. This might seem unimportant, but not always. In some installations, a shock with a slightly longer compressed length than the original part won’t allow the hatch or lid to fully close.

In some installations, a shock with a slightly longer compressed length than the original part won’t allow the hatch or lid to fully close.

Compressed length can be difficult to measure on shocks with a high force rating, but you can get a good idea by measuring the length of the rod (the thinner part of the shock that slides inside the thicker part) and subtracting that from the extended length.

Throw

The third length measurement for gas shocks is the difference between the compressed length and the extended length, usually referred to as “throw.” Throw is simply how far the shock extends. If the compressed length is 8” and the extended length is 12”, then the throw is 4”.

How to Find the Force Rating

Determining the correct force rating for replacement gas shocks is harder than finding the right length. If the old shock still has its full strength, its force can be at least approximately measured by pushing down on a bathroom scale with one end of it. The number of pounds the scale reads while the gas shock is being compressed is the approximate force. But the most common reason for replacing gas shocks is that they’ve lost some of their strength, and in that case, measuring won’t tell you much.

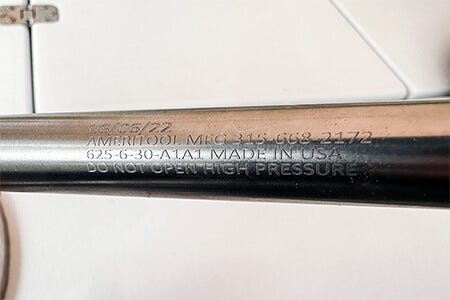

Nearly all manufacturers of gas springs include the force rating in the part number that is printed or engraved on the spring.

Instead, look for identifying markings on the barrel (the thick part) or the shock. Nearly all manufacturers of gas springs include the force rating in the part number that is printed or engraved on the spring. Where exactly the force rating is located within the part number varies by manufacturer, but here are some commonly used formats. In these examples, ‘#’ represents a numeral and ‘FR’ represents the force rating, usually in the form of two numerals.

- 625-#-FR or 750-#-FR — Ameritool gas spring part numbers normally begin with either 626 or 750, followed by a dash, a number, another dash, and then the force rating. There may be four more letters and numbers after the force rating that denote the types of end fittings.

- SL##-FR-# or ST##-FR-# — Attwood gas spring part numbers begin with SL (for painted) or ST (for stainless steel) followed by two numerals, a dash, the force rating, and another numeral. For OEM springs, the last numeral is 1; for aftermarket springs, the last numeral is 5.

Force ratings commonly found on boats and RVs range from 10 lbs. to 150 lbs. in increments of 10.

- LGP#-###-FR or LGP#S-###-FR — LaVanture gas spring part numbers begin with LGP followed by a numeral. Stainless springs have S after the numeral. That’s followed by a dash, a three-digit number, another dash, and then the force rating.

- 18## — Taylor Made gas spring part numbers consist of a four-digit number beginning with 18. On some springs, the four-digit number is followed by a dash and then the force rating. Others, though, don’t have the force rating in the part number. Refer to the company’s website for a full list of part numbers for standard and stainless steel gas shocks.

Other manufacturers have different formats, but the force rating is most commonly located at the end of the part number. Force ratings commonly found on boats and RVs range from 10 lbs. to 150 lbs. in increments of 10. Some small shocks used for electronics box doors may be as little as 5 lbs.

How Much Does Force Rating Matter?

In some cases, the part number on an old gas shock is faded, worn or rusted beyond recognition. What do you then? It can be tempting to simply order a replacement that you know has more than enough force. After all, it’s better to have too much force than not enough, right?

Well, not exactly. We strongly recommend trying to replace your old gas shock with a new one that has the same force rating. Obviously, a shock without enough force won’t do its job, but a shock with too much force is also a problem. That’s because it puts unnecessary strain on mounting brackets, fasteners and even your hatch itself.

A shock with too much force puts unnecessary strain on mounting brackets, fasteners and even your hatch itself.

Remember that gas shocks don’t “turn off” when the hatch is closed. Instead, they just keep pushing. And over time, 80 or 100 lbs. (for example) of sustained pressure can weaken the fiberglass or aluminum around the bracket fasteners, pull out screws, and even deform hatch panels.

If you’re having trouble figuring out what force rating you need, please give us a call. At Boat Outfitters, we have years of experience helping boaters and RV owners find the right replacement gas shocks.

Gas Shock Brands

People replacing worn-out gas shocks often ask if they need to buy the same brand as the original part. Except in very rare cases, the answer is no. The kind of gas shocks used on recreational boats and RVs are generally interchangeable. If you can find a shock with the right length measurements and force rating, the brand doesn’t matter, at least in terms of fitment.

If you can find a shock with the right length measurements and force rating, the brand doesn’t matter, at least in terms of fitment.

In terms of quality, though, brands do differ. We carry gas shocks from several different manufacturers, all of which are well-established American companies. Lower-quality gas shocks tend to have shorter lifespans as a result of failed seals and lower grade metal. Wherever you buy, we strongly recommend sticking with brand-name gas shocks like those from Ameritool, Attwood, Taylor Made, LaVanture, Enidine, Guden, Bansbach and others.

Gas Shock End Fittings

The vast majority of gas shock applications on recreational boats and RVs use the same end fitting — a 10mm ball socket. These fittings snap into place over ball-shaped studs that attach to the mounting surface with screws or bolts. A few heavier-duty gas springs use 13mm ball studs instead of 10mm. Just measure the diameter of the stud after removing the old shock to be sure.

Not all 10mm ball sockets look alike, but any 10mm ball socket will fit any 10mm ball stud.

Note that not all 10mm ball sockets look alike. Most are made of black composite, while a few are made of stainless steel. Some have a removable round composite “cap” that holds the ball in place. Others have a captive spring clip for the same purpose. Regardless, any 10mm ball socket will fit any 10mm ball stud.

Black Painted vs. Stainless Steel Gas Shocks

Black-painted and stainless steel gas shocks are interchangeable with one another. If you’re replacing a black shock, you can upgrade directly to stainless steel with no modifications. Likewise, if your new shock won’t be exposed to the elements much, you might want to replace an old stainless part with a new painted part to save money.

For RVs and most freshwater boats, black-painted gas shocks are just fine.

The difference is simple: stainless steel shocks last longer than painted shocks in the marine environment. Especially in applications where they’re frequently exposed to saltwater — such as baitwell lids or fish box hatches — stainless steel shocks will have a longer service life. That being said, they also cost significantly more — on the other of two to three times as much as a non-stainless gas shock of the same length and force rating. For RVs and most freshwater boats, black-painted gas shocks are just fine.

Removing and Installing Gas Shocks

Most gas shocks found on boats or RVs have one of two basic styles of 10mm ball socket end fittings. Both are easy to remove and install.

Cap Style

The first uses a removable round cap with several “blades” that fit into slots around the edge of the socket.

To remove the shock, use a small flat-blade screwdriver to gently pry the cap off. With the cap removed, pull the fitting firmly off the ball stud. You should be able to do this without tools, but it sometimes requires some force.

To install a new gas shock with this style end, simply remove the cap, push the socket onto the ball stud until it snaps into place, and then push the cap into place.

Clip Style

The second style uses a roughly C-shaped metal spring clip to retain the ball in the socket.

To remove the shock, insert the blade of a small standard screwdriver under the spring clip and pry it up and away from the rest of the fitting while simultaneously pulling the fitting off the ball stud.

Try not to pry the clip all the way off. Note that some newer models are removed by squeezing the spring clip with pliers rather than prying it up with a screwdriver.

To install a new gas shock with a metal spring clip-type fitting, simply snap it into place. There’s no need to pry or squeeze the spring clip.

As a general rule, install your shocks in the same orientation the old shocks were installed. If reasonably possible, it’s better to have the rod (smaller) end of the shock lower than the barrel (bigger) end when the hatch is closed. This extends the life of the shock by keeping the seal better lubricated.