If there’s one thing you can count on when refitting a boat with updated electronics, it’s that the new units won’t fit in the same cutouts as the old ones. Displays have gotten wider in relation to their height, and one or two large multifunction displays can now do the work that was previously done by multiple smaller dedicated displays.

That means marine electronics shops like NautiNav, in North Dartmouth, Mass., often have to figure out how to cover old cutouts before installing new units. And in many cases, the easiest, cleanest approach is simply to scrap the old “Swiss cheese” dash panel and fabricate an entirely new one.

Contents

NautiNav's Dash Panel Upgrades

For years, NautiNav owner Neil Gouveia and his team hand-cut their own panels from sheets of King Starboard using a table saw router and jigsaw. Customers were happy with the results, but, says Gouveia, “It was very time-consuming.” Additionally, NautiNav was limited to Starboard panels, since fabricating with marine acrylic, which offers a glossier finish and more refined look, requires specialized tools and techniques.

Then, while placing an order for Starboard material from Boat Outfitters last year, Gouveia noticed that the company advertised custom-cut dash panels. Curious, he wondered if ordering ready-to-install panels could save him time. “I reached out to them about it,” he says, “and they said, ‘Sure, we can make anything you want.’”

It took just one order for Gouveia to realize that partnering with Boat Outfitters was a win.

It took just one order for Gouveia to realize that partnering with Boat Outfitters was a win not just for him but for his customers too. “If you look at the time I’d spend making a panel by hand at my hourly shop rate, most of the panels I’ve ordered have been roughly the same cost. So it’s similar in price for the customer, but it saves me time, and in the long run, they look nicer.”

Navigating the Ordering Process

The ordering process is a surprisingly smooth one, considering that more than 1,000 miles separate North Dartmouth from Ocoee, Fla., where Boat Outfitters is based. When he needs a panel made, Gouveia takes careful measurements of its overall size, and sends those, along with information about material, thickness, color, mounting style, and the approximate locations of displays and other devices to be installed, to his Boat Outfitters project manager, Theo Dudley. Boat Outfitters keeps mounting templates for most devices on file, so there’s no need for Gouveia to supply those.

Options To Consider

Most NautiNav customers choose acrylic over Starboard for its high-gloss finish. Starboard is considerably less costly but has a lightly textured matte finish. Also, Boat Outfitters doesn’t recommend Starboard for black panels, since it tends to show scratches and scuffs. Acrylic panels can be made in black as well as several different whites and off-whites.

NautiNav and their customers also favor the seamless, high-end look of stud mounting when access to the back of the panel is possible. Instead of screw holes, stud-mount panels have threaded studs on the back that are inserted through pre-drilled holes in the dash. Then nuts and washers are installed from behind, leaving no visible screw heads. Stud-mount panels ship with plywood templates for marking and drilling the stud holes on the dash.

With dimensions, material, color, mounting style and device information in hand, Dudley and the Boat Outfitters engineering team then design the panel and create a digital mockup that they email back to NautiNav for approval or changes. For some particularly challenging projects, Boat Outfitters actually ships a CNC-cut plywood mockup of the panel that NautiNav can test fit, modify as needed and return. When the design is finalized, Boat Outfitters cuts the panel on a CNC router and ships it to NautiNav. From beginning to end, the process typically takes three to four weeks.

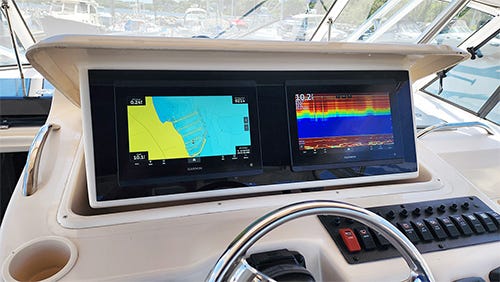

When it came time to upgrade his dual Garmin displays to newer models with a different footprint, the owner of this Grady-White wanted the installation to look factory. So NautiNav owner Neil Gouveia called Boat Outfitters for a gloss-black, CNC-cut acrylic panel with completely hidden fasteners.

‘Like It Came from the Factory’

The results have been excellent. “Communication is great,” Gouveia says. “Theo has been awesome. Any red flags or concerns, he’ll email me right away to double-check.”

On Gouveia’s most recent custom panel job, NautiNav replaced a pair of older Garmin displays in the pop-up electronics box of an express-style Grady-White with new Garmins. With their narrower bezels and wider screens, the new displays of course didn’t match the existing cutouts in the fiberglass mounting panel.

The easiest and least costly option would have been to use Starboard or acrylic trim plates

The easiest and least costly option would have been to use Starboard or acrylic trim plates to cover the gaps around the new displays. But the owner didn’t want his helm to look jury-rigged. “We were installing state-of-the-art electronics in a beautiful boat,” Gouveia says. “It had to look absolutely professional.” So he and the boat owner chose a gloss black acrylic panel with hidden mounting studs that would cover the old fiberglass mounting surface and provide a completely clean slate for the new displays.

“When it was done,” he says, “the owner looked at it and said, ‘This looks like it came from the factory like this. It doesn’t look like a refit at all.’ And that’s the best thing to hear for me. That’s a big goal.”

The owner of this center console wanted to add a second display, but there wasn’t room in the original recessed electronics box (left). Instead, NautiNav recommended a new panel to cover the old box and accommodate the second display. Boat Outfitters mocked up the design in plywood for test-fitting (center), then cut the final panel from white acrylic using a CNC router (right).

Another Successful Refit

As part of another recent project, NautiNav was challenged with figuring out how to add a second Garmin display to a center console that, at first glance, simply wasn’t big enough. The console had originally been designed with a recessed electronics mounting surface behind a protective door, and there wasn’t room between the single existing display and the VHF and stereo to fit another display.

But thinking outside the box (both figuratively and literally), Gouveia saw how he could use a completely new panel to not only create enough additional mounting real estate for the second display but also to get rid of the unused and outdated recessed box. He talked over the plan with Dudley at Boat Outfitters, sent his measurements and got back a plywood mockup for test-fitting.

After making small changes based on the test fit, Boat Outfitters cut the final panel from gloss white acrylic and shipped it. Because of limited access from the back of the panel, stud-mounting wasn’t possible, but the result was still a major upgrade in terms of both form and function. “I don’t know if I would have been able to cut a panel that precisely,” says Gouveia, “but they were able to make it so it fit into this recess perfectly like it was meant to be there. This was another one where the boat owner was just through-the-roof excited about how it came out.”