When they first hit the recreational marine market, friction hinges were widely hailed as a development that would completely replace gas shocks and support springs on hatches. Now, a decade later, friction hinges remain popular with both boat builders and DIY boat owners but are no longer seen as the be-all and end-all they were at first. Instead, boaters and builders have learned that, like just about everything else, friction hinges are ideal in some applications and not-so-ideal in others.

Contents

Friction Hinge Advantages

Friction hinges have a few distinct advantages over other hatch support options, like gas shocks and support springs. If you’re thinking about using friction hinges on a new build or replacing existing hinges with friction hinges, here’s what you need to know:

Controlled Positions

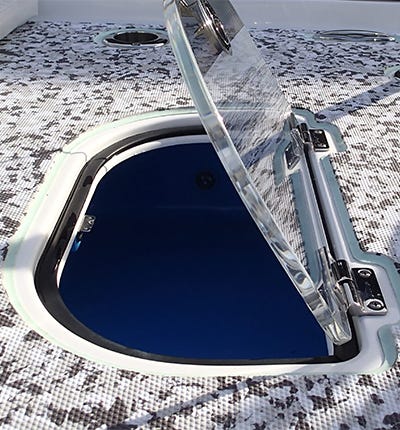

With gas shocks and support springs, your hatch has two positions: “closed” and “open.” But friction hinges hold your hatch wherever you leave it. The hatch will not slam closed when released with friction hinges which limits the chance of breaking the lid itself or the latch.

They're Self-Contained

With gas shocks or support springs, the shock or spring can get in the way, partially blocking access to the hatch when open. Also, when the hatch is closed, the spring or shock takes up room inside. Friction hinges achieve the same without additional hardware getting in the way.

Easy Installation

Provided you can find friction hinges matching your existing hinges' footprint and hole pattern, installation is very easy. Gas shock installs are notoriously difficult to measure for and require locating and drilling new holes in both your hatch lid and the lip or wall of your compartment. Upgrading to friction hinges is essentially “plug-and-play.”

Disadvantages to Friction Hinges

Although friction hinges have a lot of advantages and seem like the best option for many hatch and door applications, there are some disadvantages.

Friction Hinges Don’t Last Forever

The resistance of friction hinges is created by special friction washers made from a copper alloy called phosphor bronze. Although the analogy isn’t exact, you can think of them sort of like the drag washers on fishing reels. And, just like reel drag washers, friction washers gradually wear out. How long that takes to happen depends on a lot of factors, but the frequency of use is a big one.

The more often you open and close a hatch, the sooner the friction hinges will wear out.

The more often you open and close a hatch, the sooner the friction hinges will wear out. The quality of your installation also plays a big role. If the barrels of your hinges aren’t aligned exactly, they’ll wear out much more quickly. Although some boaters have reported hinges wearing out in a year or less, the typical service life is much longer.

Friction Hinges Aren’t Adjustable

Friction hinges aren’t designed to be user-adjusted, and attempting to adjust the tension typically voids the warranty.

There’s a good chance doing so will break your hinge too. Most friction hinges have a torque rating of 45-inch pounds.

A few light-duty hinges are rated at 20-inch pounds. The only real way to adjust how “stiff” your hatch lid feels is to increase or decrease the number of hinges — which is difficult on DIY retrofits.

Friction hinges aren’t designed to be user-adjusted.

In some cases, if your friction hinges aren’t quite strong enough, they may hold your hatch lid in a vertical or near-vertical position but let it close otherwise. In other cases, like very small hatches that don’t give you much leverage on the hinge, lids may feel excessively stiff and require a lot of force to open.

In contrast, gas shocks are available in a variety of force ratings and lengths to work with hatches of different sizes and weights. Additionally, the effective force of a gas shock can be reduced by mounting it to the hatch lid closer to the hinge or increased by mounting it farther from the hinge.

Other Considerations

Besides the functionality of friction hinges, there are a few other considerations to think about when determining whether friction hinges are the best option for your application.

Hatch Size

Friction hinges are great for lots of applications, including livewell lids, electronics box doors, glove box doors, smaller anchor lockers, access doors, etc. They’re not as well suited for large, heavy hatches like in-deck fish boxes, coffin boxes or engine compartment hatches. That’s because even if you use enough friction hinges to effectively support the hatch, the hinges still put a great deal of strain on the hatch lid and deck.

Little Leverage

Unlike gas shocks and support springs, which attach to the hatch away from the hinge, giving them some mechanical advantage, friction hinges have very little leverage on the hatch. To understand this, imagine trying to hold a large hatch open at 45 degrees with the tip of one finger underneath the center of the hatch.

Now, imagine trying to do the same with your finger just an inch or two from the hinge edge. The latter is what friction hinges do. In some cases, the forces can actually damage the laminate of the hatch lid or deck.

Unlike gas shocks and support springs, friction hinges have very little leverage on the hatch.

Even on small and medium hatches, it’s preferable to through-bolt friction hinges and use the largest washers or backing plates possible. This helps prevent flexing of the laminate, screws pulling out and fastener holes becoming enlarged.

Hole Pattern

When replacing existing hinges with friction hinges, be sure to look at the dimensioned drawings of the friction hinges you’re considering and measure carefully. In some instances, even though a friction hinge has a very similar shape and overall dimensions, the hole pattern will be slightly different. That’s not an insurmountable problem, of course; as long as the form factor of the new hinge is the same as the old, you can fill the old holes and drill new ones. Just know what you’re getting into up front.

Are They Worth the Cost?

It’s easy to get sticker shock the first time you look at the price of quality friction hinges, which is something on the order of three to four times the price of a “standard” marine hinge of equivalent size and quality. But that’s not the whole story. To get a true picture, compare the price of friction hinges to the price of standard hinges, plus the cost of a gas shock (or shocks) with mounting brackets. In most cases, the total cost is pretty similar, and the friction hinges are much simpler to install.

Friction hinges are a great upgrade, offering real advantages over gas shocks and support springs.

The fact is that when used in appropriate applications, friction hinges are a great upgrade, offering real advantages over gas shocks and support springs. They are clean, compact, easy to install, and offer the added benefit of holding a hatch or lid in any position desired. Questions? Don’t hesitate to give us a call and chat with one of our experts.