Justin Ballotte was named the winner of Boat Outfitters’ inaugural DIY Genius Contest in November 2024 and received a $500 gift card. Ballotte used four Boat Outfitters access doors and a tilt-out glove box on the 21-foot strip-plank composite center console he and his family built in their Connecticut garage. We asked him more about the build, the boat, and how he chose and spec’d the Boat Outfitters parts he used.

Console Access Doors

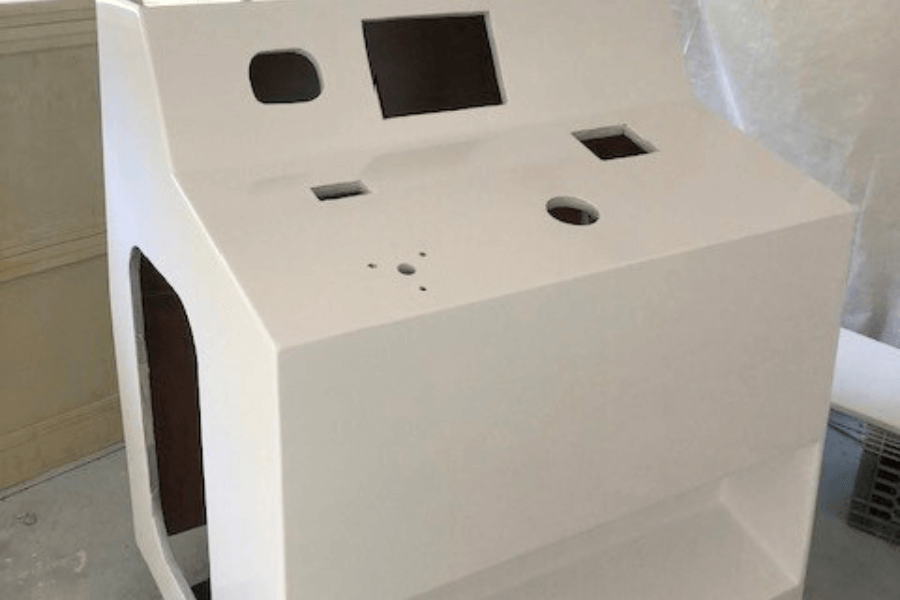

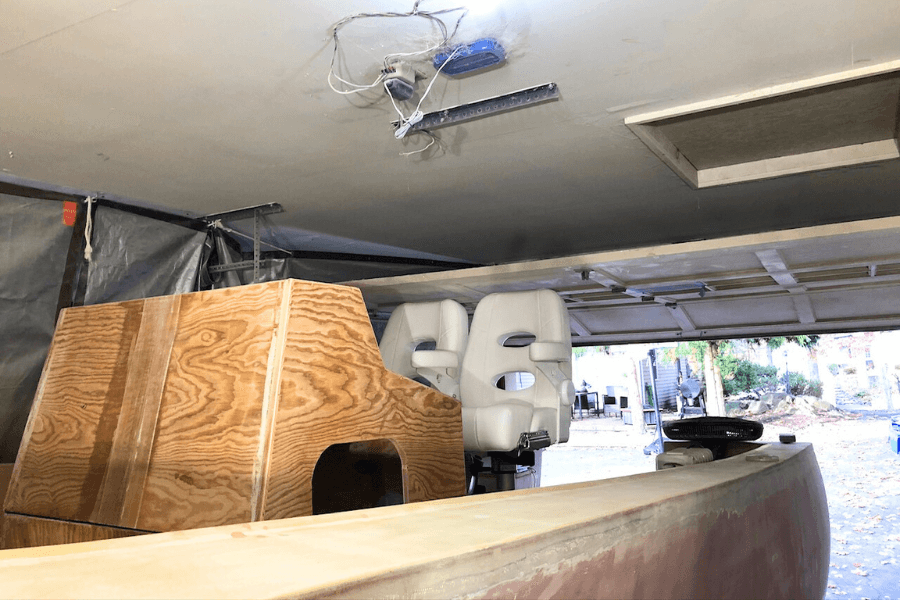

When it came time to add access doors to Marlin Mayhem, the 21-foot center console he and his family had built in their Connecticut garage, Justin Ballotte wasn’t going to cut corners — not with as much time and care and sweat as they already had in the boat.

They had built the strip plank hull quite literally from the ground up, first constructing a strongback, then frames, then forming the hull itself with white cedar planks they had milled themselves, then glassing, sanding, fairing, rigging, and painting. “It was a lot of work,” Ballotte says. “A lot of sawdust. Hundreds of hours running power tools.”

Contest winner Justin Ballotte, along with his wife and three sons, built a 21-foot center console, Marlin Mayhem, from scratch in their Connecticut garage.

So Ballotte wanted access doors that would do justice to the rest of the build, and that meant no off-the-shelf molded plastic parts. Instead, he turned to Boat Outfitters to craft CNC-cut Starboard doors to his exact specifications. On the console, Ballotte decided to install not one but two matching Aluminum Framed Boat Access Doors — on one each side — for easier access to the wiring, rigging, and storage inside.

He chose radiused corners and low-profile aluminum frames to complement the sleek, clean look evident throughout the boat, making the doors as wide as they could be without hitting the gunwales when opened. “This wasn’t a measure twice, cut once thing,” Ballotte says. “This was more like measure 10 times, order once.” Louvers were added for improved air circulation inside the console.

Ballotte chose to install the doors with the hinges along the aft edges so they don’t swing shut by themselves when opened. “It might not be for everybody,” he says, “but we like it. If we built hull #2, I’d order the console doors exactly the same.”

Because the console was crafted from 3/4” marine plywood, which holds screws very well, Ballotte opted for installing the doors with stainless steel screws.

Aft Box Access Doors

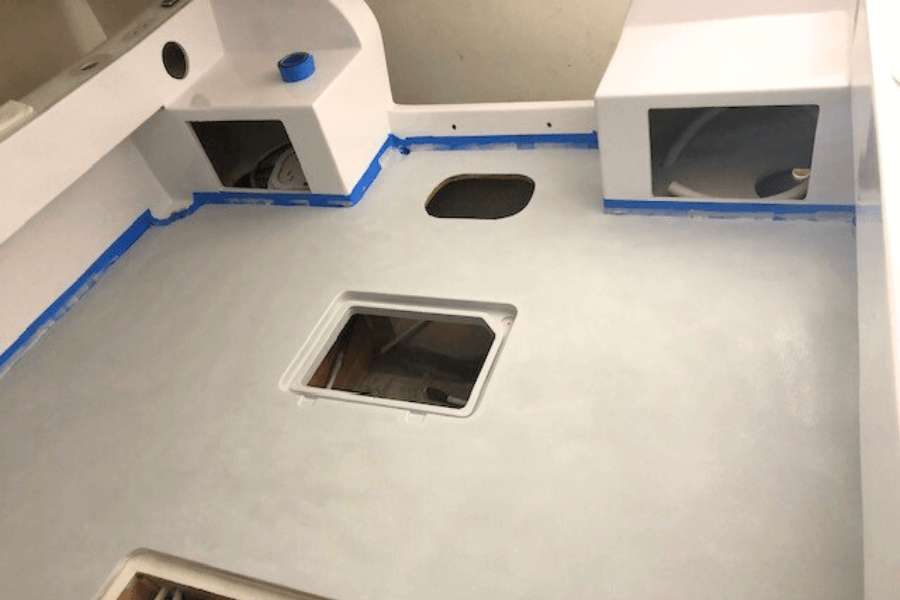

The design Ballotte was building from featured an open cockpit with a traditional notched transom, but he made the decision to fabricate boxes in the aft corners for additional seating. A top priority, he says, was plenty of safe, comfortable seating for sandbar days with family and friends.

As an added benefit, the boxes — built, like the console, from fiberglassed 3/4” marine ply — help conceal wiring, hydraulic hoses and fuel lines running between the console and the engine.

A top priority was plenty of safe, comfortable seating for sandbar days with family and friends.

Here too, access for maintenance and storage was key. For these access doors, Ballotte chose Starboard Double Open Out Boat Doors with Starboard frames and stainless steel latches. Powder-coated aluminum frames are lower profile with a sleeker aesthetic but, because powder-coating can chip and let saltwater reach the aluminum underneath, they’re not well suited to applications where impacts from sinkers, anchors or similar objects are likely. Near the deck in the cockpit of a fishing boat is a perfect example. Ballotte positioned the doors a couple inches above deck level to keep water out.

The starboard box is dedicated mainly to rigging; the port box is the perfect place for gear that doesn’t need to be in a bone-dry compartment, like fenders and lines.

Console Glove Box

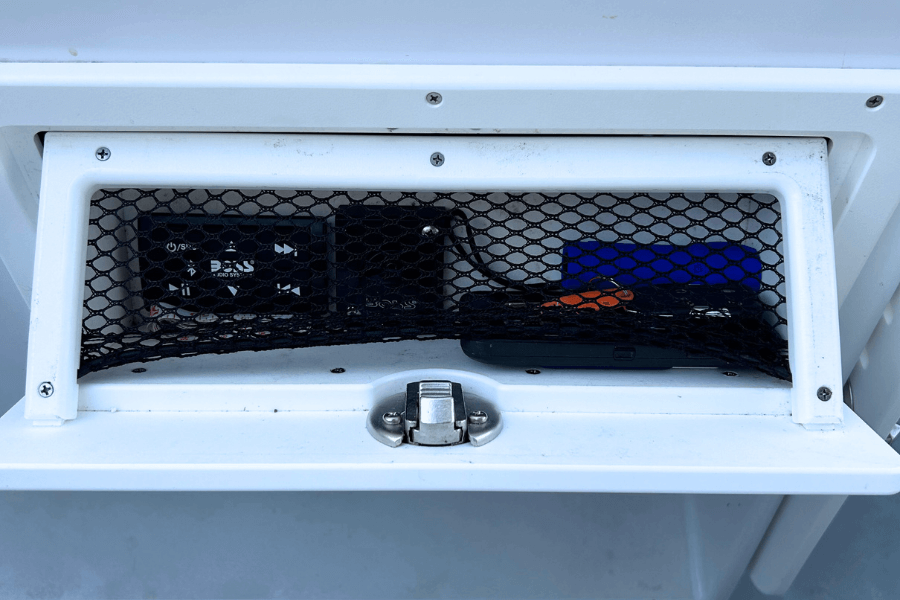

Throughout Marlin Mayhem — but especially on the console — a clean, sleek, sparing look was a priority for Ballotte. Unlike many boaters, who want their dashes to look like the cockpit of an F-35, Ballotte wanted as few screens, gauges, panels, and switches as reasonably possible.

“I’m kind of old-school,” he says, “with a compass on top of the console centerline and nothing else on either side.”

To keep the dash as simple as possible, Ballotte chose to mount their stereo head unit inside a glove box. Once the system is powered on, he says, all control functions are available through his phone, so there’s no reason to have the head unit exposed on the dash.

As an added benefit, the Tilt Out Glove Box with Retaining Net that Ballotte chose is the perfect place for car keys, phones and wallets. A USB outlet also mounted through the back of the box allows phone charging while on the water.

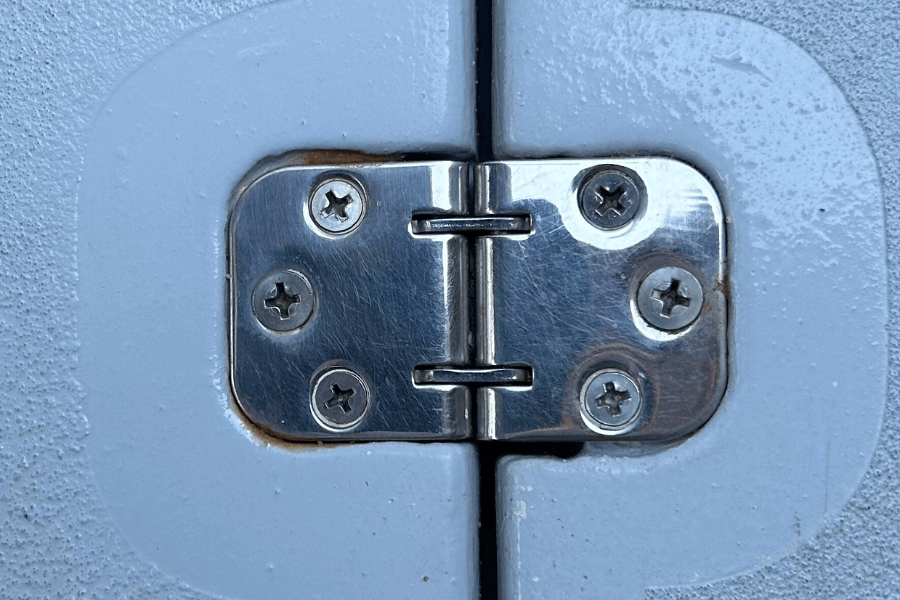

Hinges and Other Hardware

Most of the hardware on the boat — latches, hinges, rod holder, cleats, etc. — also came from Boat Outfitters. “For this kind of project,” Ballotte says, “it was almost like a one-stop shopping.” He chose the hinges for the boat’s hatches carefully, again prioritizing a clean, low-profile appearance.

That meant recessing the hinges into the deck for a flush fit. To do so, Ballotte traced the footprint of each hinge on deck and then carefully routed the recess out by hand. “I’d practice on six different pieces of wood if need be,” he says.

DIY Advantages

With roughly 100 hours on Marlin Mayhem now, Ballotte and his family still love the design and the details.

The boat lives on a trailer in Rhode Island, where it serves as a “family-oriented weekend excursion and fishing boat,” as Ballotte puts it.

That means it might be loaded down with half a dozen kids one weekend for a trip to the sandbar for clamming and skimboarding and loaded with offshore tackle the next for a run offshore in search of tuna.

“Overall, the hull and performance of Marlin Mayhem check so many boxes for us.”

They’re also satisfied with their decision to build their boat instead of buy it.

First, the design combines certain elements Ballotte couldn’t find together in a 21-foot production boat — a Carolina-flared bow, wide reverse chines, aggressive deadrise, ample seating, and Llebroc helm chairs.

The helm chairs combined with the console footrest keep the crew safe and secure on longer runs offshore. “We had to ensure my wife and younger boys, now avid boaters, are comfortable behind the console in choppy weather.”

What It’s All About

Plus, of course, there’s the simple satisfaction that comes with having built something with your own hands.

“Just having something that we built ourselves in our garage is a big deal,” Ballotte says.

“It was the family experience that mattered first and foremost because everybody was involved in so many different ways and different steps along the way.”

Charlie, Ballotte’s youngest son, started out with a plastic toy screw gun and progressed to laying out and measuring the deck and boxes. Zachary, the middle, became well versed in layout concepts and worked with fiberglass and epoxy throughout the build. And Riley, the oldest, caught his first saltwater fish aboard Marlin Mayhem and later became a natural when fishing Block Island Sound.

“Of course,” says Ballotte, “credit to my wife Liz, who is on her way to handling the boat, for the support and patience throughout the entire process. Not to mention, she is fierce at catching seabass. Those early memories and experiences are exactly what it’s all about.”

“Those early memories and experiences are exactly what it’s all about.”