If you’ve ever stalked redfish, bonefish, permit, or other skinny water predators, you know how spooky they are. If you haven’t, suffice it to say that when they’re feeding on the flats, these fish are about as skittish as the proverbial long-tailed cat in a room full of rocking chairs.

Bird shadows, lure splashes, loud voices, footfalls on deck, and even the gentle slap of wind ripples against fiberglass will send them bolting. Because of that, designers of poling skiffs work hard to make their boats quiet by eliminating so-called “hull slap” — the noise made by small waves hitting the skiff’s hull.

The Solution

There are lots of causes of hull slap, but one of the worst culprits is a hard chine — or, worse yet, a reverse chine — forward. The spot at which a hard chine line sweeping downward from the bow enters the water is always noisy.

The solution is simple enough: a rounded shape forward with no hard chines. Without hard chines, when the skiff is on the plane, water tends to “slide” up its sides, rather than being directed down and away from the boat by the chines. And that, combined with low freeboard, translates to a very, very wet ride.

Dolphin Super Skiff

Most newer poling skiff designs address this with integrated spray rails — molded “overhangs” running roughly parallel to the sheer line along the forward half or so of the hull, but well above the resting waterline where they won’t make noise. Many earlier designs, though, lack molded-in rails.

Among those is the vaunted Dolphin Super Skiff, a 16-foot classic with an aggressive 18-degree deadrise beloved by South Florida guides and anglers for its exceptionally soft rough water ride but also notorious for its wetness. Still in production today, the Super Skiff has now been modified to include molded-in spray rails.

In 2017, Tim Butts and his son completed a full, keel-up rebuild of the 1984 side console Dolphin Super Skiff that Tim had bought the year before, converting the boat to a center console.

Tim's Upgrade Journey

All of which brings us to Tim Butts, an avid Cape Coral-based angler who runs a beautifully restored and meticulously maintained 1984 Super Skiff. After buying the boat in 2016, he and his son did a full rebuild in 2017, converting it from a side console to a center console, extending the forward deck, adding a live well, battery boxes, trolling motor, hydraulic steering and trim tabs, and then, two years later, repowering.

He loved the ride in rough water and stealth on the pole. But, he says, “This thing was like driving a submarine. The guys I fish with would always bring rain jackets, even on calm days. You couldn’t move spots without stopping to clean your sunglasses.”

Aftermarket Spray Rails

When, after a breezy trip to the Keys last spring, Tim finally made up his mind to get serious about fixing the wet ride, it took him only a few minutes online to learn that not only had other Super Skiff owners added aftermarket spray rails, but even the factory had installed them for a time before eventually modifying the mold to include integrated rails.

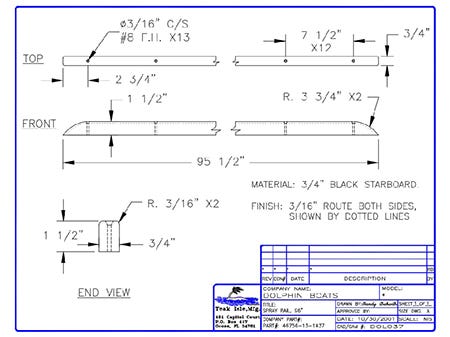

During his search, Tim even came across an old engineering drawing from 2001 of the OEM spray rails that Dolphin used at the time, clearly marked as the work of Teak Isle Mfg, Boat Outfitters’ parent company. They were machined from King Starboard, slightly less than 8 feet long, 1-1/2” tall, and 3/4” thick, with rounded over edges and a 3-3/4” radius on each end.

A bit of online research turned up a 2001 engineering drawing of the OEM spray rails Dolphin installed before adding rails to the Super Skiff mold. They were supplied by Teak Isle, Boat Outfitters’ parent company. From there, it was easy. Tim called Teak Isle and was referred to Boat Outfitters, who still had the original design for the spray rails and was able to quickly machine a pair. They arrived on his porch within a week.

Spray Rail Installation

Installation, Tim says, was fairly straightforward. First, he drilled and countersunk holes in the rails on 7-1/2” centers as shown in the old drawing. Then he clamped the rails in place using standard woodworking clamps, marked their forward and aft ends with tape, and used the holes he had drilled in the rails to drill pilot holes in the boat.

With the holes drilled in the boat, Tim ran a slim bead of black adhesive sealant along the surface of the spray rail, dabbed a bit of sealant into each screw hole and then screwed the rails in place using #8 x 2” stainless steel screws and a hand screwdriver to prevent stripping any of the holes. Avoiding making a mess with the sealant, he says, was the hardest part of the whole project.

After drilling and countersinking the spray rails, Tim clamped them in place and marked and drilled pilot holes in the boat, then applied a bead of sealant and attached with #8 x 2” screws.

Rock-Solid and Dry

The rails, Tim says, are rock solid and, just as importantly, do their job very effectively. On his first trip out after installing them, he and a friend fished the Everglades on a breezy fall day, crossing several open bays with 6” to 12” chop that in the past would have soaked them both. “The guy that was with me,” Tim says, “fishes with me all the time, and he said, ‘This is insane, what a difference!’ We had no spray at all.”

The finished product, Tim says, is not only rock solid but also extremely effective at controlling spray.

DIY Spray Rail Applications

Note that compatibility with aftermarket spray rails like these depends largely on the configuration of the hull-to-deck joint. This style generally requires a deck that extends out past the hull sides, creating a significant overhang with a smooth, horizontal surface on the underside. This surface must be wide enough to accommodate the rail and have enough fiberglass above it for screws to bite solidly.

This surface must be wide enough to accommodate the rail.

This same style of spray rail has been used widely and successfully not just on the Dolphin Super Skiff and Renegade, but also on Maverick Mirage and HPX series skiffs as well as Mitzi skiffs and some Beavertail models. Like Dolphin, Maverick has offered factory-installed Starboard spray rails on some models. The length, height and thickness of the rails can be easily altered by Boat Outfitters to match your specifications.